Design Considerations for Heavy Industrial and Airport Pavements

1. INTRODUCTION

Airports are major economical investments in the infrastructure industry as they play an essential role in the transportation of people and good for a country. Airport runways are an important part of the functional workability of an airport, with an increase in demand an increase in airport traffic can be noticed causing a decline in the runway quality (Ahmad Zaini, A. Aziz, Kassim & Mustafa, 2016). Pavements are designed to transmit loads to the lower sublayers providing a smooth surface supporting a vehicle traveling on the surface, most pavements are designed for a 20 to 30-year service life making them a long-lasting asset (Jaskula & Judycki, 2016). Airports consist of three major pavement areas, runways, taxiways and aprons which are developed to provide enough support for loads inflicted by aircrafts and to develop a firm, smooth and skid resistant surface (Airport pavements 2017). Many forms of pavements have been used in the history of infrastructure with various forms providing different benefits. Two major styles of pavements are seen in the runway areas of airports, flexible pavements and rigid pavements, these are selected based on the various requirements and conditions the runway may be subjected too. Both runway constructions can experience similar failures and fatigues, we often notice pavements experience fatigue due wearing from constant use and weather deterioration. Fatigue can be seen in several ways, these can be cracking, rutting, and thermal cracking as well as potholes, there is a shift in focus from maintaining airport pavements to preventing the pavements deterioration (Ahmad Zaini, A. Aziz, Kassim & Mustafa, 2016).

2. BACKGROUND

Types of runways

Runways are categorised into three area, visual, non-precision instrument and precision instrument. Visual runways are usually implemented at small airstrips and are for private and not commercial use, however these types of runways can be seen implemented in third world countries in small towns and village areas where large infrastructure is not accessible. Visual runways do not necessarily comprise of markings and outlines however they do not provide an instrument-based landing procedure and the use of the runways depends solely on the ability of the pilot to visually identify the runway. Non-precision instrument runways are used in small to medium sized airports, these can have markings on them depending on the surface. The non-precision runways work with non-directional beacons which provide guidance to the aircrafts on approach. Precision instrument runways are found on larger airfields with a large amount of traffic, these runways feature markings to assist with directional flow of traffic and provide guidance to the pilots when operating. On approach a precision instrument runway provides both horizontal and vertical guidance to aircrafts of approach (“Chapter 4 Landside Technologies and other Airport Infrastructure”, 2019).

Types of pavements implemented for runways

Runways are primarily seen with two kinds of pavement designs, flexible or pavements. Rigid pavements are reinforced concrete pavements composed of course and fine grain aggregates, whereas flexible pavements are made with a larger plasticity allowing them to be more flexible and shock absorbent. Flexible pavements are made from a mixture of sand, gravel compacted into bitumen (“Runway construction – Designing Buildings Wiki”, 2019). The major difference in the two pavement styles is their ability to distribute load, flexible pavements distribute the load to the lower sub layers whereas with a rigid pavement the load is carried by the top layer and only a very slight load is actually distributed to the sublayers below. Rigid pavements often have a higher load bearing capacity, as flexible pavements have a lower modulus of elasticity causing them to be weaker as the strength also depends on the sublayers whereas a rigid pavements strength depends solely on the strength of the reinforced concrete member. The pavement materials used for airfields and roadways are very similar, however with the difference in design variances such as thickness for the loading capacity of the pavement, figure 1 outlines the general design concept adopted in airfields ‘keeled’ pavement where the middle of the pavement is thicker than the edges and this is common for both flexible and rigid pavement designs (Deilami & White, 2018).

Common distress and damage experienced

With pavements being designed for a service life of 20 to 30 years, in most cases replacement of the wearing course is common. The purpose for many replacements is to reinstate the functionality of the pavement which might have deteriorated due to regular wear. Often this is noticed through the decreased friction in the pavement or reduced smoothness experienced, other distresses that are experienced in pavements over time are ravelling, potholes and cracking that occurs over time and can occur due to various conditions (Jaskula & Judycki, 2016).

Cracking experienced in airport pavements is largely seen due to slow moving heavy aircraft loading as well as environmental conditions, joint performance and subgrade material in the airfield pavement (Mehta, Cleary & Ali, 2017). A major concern in asphalt roads is reflective cracking, these can reduce the life span of the

|

Fig. 1: Typical cross sections of flexible and rigid runway pavements (FAA, 2016) |

pavement. However pavement specifications can be selected based on requirements for the airfield, if an airfield will be subjected to high flow of heavy aircrafts causing excessive loads on the airfield pavement P-304 and P-306 pavement specifications should be avoided as they as prone to reflective cracking instead a different specification may be chosen to provide a better pavement design (“Airport Pavement Design and Evaluation”, 2016). Table 1 outlines the specifications of pavement designs as defined by the U.S. Department of Transportation Federal Aviation Administration (FAA).

|

Pavement Layer |

Flexible Pavement |

Rigid Pavement |

|

Surface Course |

P-401/P-4032 |

P-501 |

|

Stabilized Base Course |

P-401/P-403 P-3043 P-3063 |

P-401/P-403 P-3043 P-3063 |

|

Base Course |

P-2094 P-2085 P-211 |

P-2094 P-2085 P-211 |

|

Subbase Course |

P-154 P-2136 P-2197 |

P-154 P-3016 P-2197 |

|

Subgrade |

P-152 P-155 P-157 P-158 |

P-152 P-155 P-157 P-158 |

|

Table 1: Typical Pavement Specifications for Pavement Layers (“Airport Pavement Design and Evaluation”, 2016) |

||

3. COMMON DESIGN CONSIDERATIONS

When designing for a new airport or any upgrades to existing airport construction it is important to consider what is available and whether the plans will be suitable for

the proposed design, even though many airport runways and taxi areas are commonly constructed with rigid pavements considerations. The flexible design is still taken into consideration before any finalisation of the design (White, 2018). The pavement types chosen for the airport runway and or taxiways are based on the properties of the subgrade material in the area, as flexible pavements transpose and share the load with the subgrade material below whereas rigid pavements do not, this is why the topography of the area is important to consider.

Get Help With Your Essay

If you need assistance with writing your essay, our professional essay writing service is here to help!

When in the early stages of planning and evaluating the site it is important to consider topography of the area that will be available and any hazard that might surround the site, when considering the topography it is important to consider the elevations as this can lead to additional earthworks required, the orientation of the runway, and any additional grading or drainage that will be required based on the site elevations (“Chapter III – Planning Considerations | Airport Passenger Terminal Planning and Design, Volume 1: Guidebook,” n.d.). When considering potential designs, it is important to consider enough grading and drainage for the pavement area, as water and frost are some of the most important factors effecting the deterioration of asphalt concrete that are subjected to it. Water and frost can cause various types of distress in pavements that can potentially lead to pavement failures such as stripping, ravelling, potholes and surface deterioration. A significant importance on drainage systems around airport pavements is produced with research into more specific pavement design methods being considered to reduce the effect of water and frost on asphalt concrete pavements (Jaskula & Judycki, 2016). Without sufficient drainage we can also notice an increase in water runoff with additional pollutants into the local water bodies, this can cause negative impacts in the local environment however airports usually use detention/retention ponds to help catch the water runoff and treat for water quality (“Chapter III – Planning Considerations | Airport Passenger Terminal Planning and Design, Volume 1: Guidebook,” n.d.).

Other trends in airport design considerations is the trend to use the surrounding real estate with the highest and best use of the surrounding terminal facilities. This trend is taking off due to growing pressured to increase economic performance to achieve maximum possible revenue with the use of local facilities around the airport terminals.

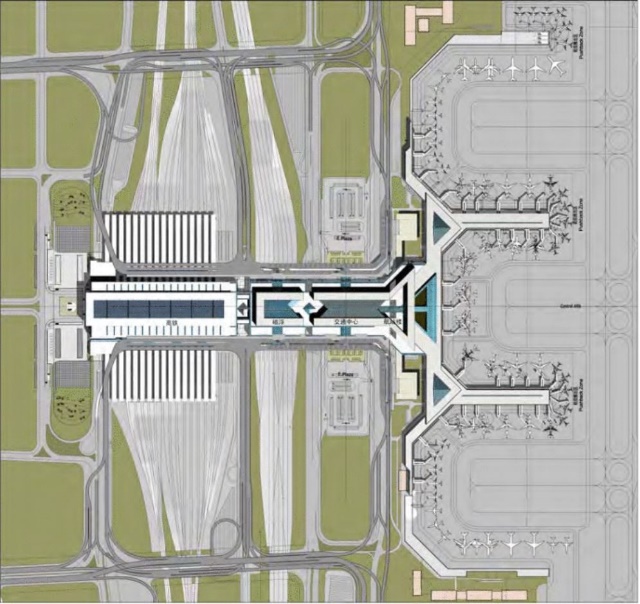

With major airports prioritising the potential of property development within mediate proximity of terminals where millions of passengers are processed, it is being realised that the closer the property is to the terminal where passengers will be processed the more potential for revenue through hotels, offices, and high end retail developments. Above is an example of integration of new passenger terminals with a major multi-model ground transportation centre at the Shanghai Hongqiao International Airport seen in Figure 2.

When deciding the location of an airport the only major consideration taken when considering the soil at the proposed location is the amount of movement in the soil

|

|

|

Fig. 2: Shanghai Hongqiao Airport |

with potential risks of earth movements and natural disasters from occurring. With airports being main hubs for disaster relief it is imperative that the airport locations are in areas with low natural disaster occurrence rates, however modern design and construction are developed to withstand major earthquakes. Japan is subject to major earthquakes and tsunamis, however after experiencing a 9.0 magnitude earthquake all major airports in Japan were operational within a few says after the earthquake with minimal infrastructure damage demonstrating the capabilities of the modern infrastructure. The only major consideration taken into account is the airport pavement requirement, however subgrade strengths usually don’t play a major part in this consideration as the top pavement design can be altered to increase the strength whether through reinforced pavements or adding a subgrade layer below a flexible pavement (Smith, 2011).

4. CASE STUDY:

Tokyo Haneda D-runway

Tokyo Haneda Airport was constructed on reclaimed land on the sea and it served as the main international airport in Tokyo from 1952-1978. The airport was first opened in 1931 when it served as the chief operating base of Japan Air Transport and it managed domestic flights as well as flights to Taiwan and Korea. The airport was then almost completely used as a military base for transport services and flight training for the Imperial Japanese Naval Air Service. International flights moved to Tokyo Narita Airport in 1978 and Haneda became the main hub for almost all of Tokyo’s domestic flight (“Haneda Airport”, n.d.).

The fourth runway, known as D-Runway, was constructed to meet the increasing capacity of the airport. Located in the mouth of the Tama river, D-runway was constructed as a hybrid structure using pile-elevated platform and land reclamation as the runway is situated 600m offshore from

|

|

|

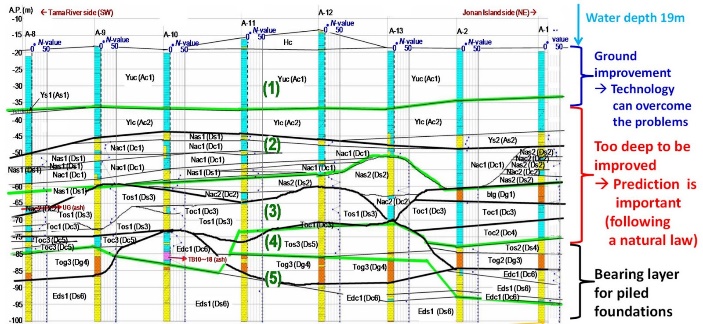

Fig. 4: Geological Layers and Depth profile (Watabe & Noguchi, 2011) |

the preceding airport island (Watabe & Noguchi, 2011, Mizukami & Matsunaga, 2016). To ensure adequate flow rate during times of flood, a pier structure with a less than 8% impediment rate of river flow was adopted. It uses a rigid pavement that is constructed with precast concrete slabs as it may have to undertake heavy loads due to the possibility of the usage of the largest passenger airline model, the A380, utilizing it. Construction that requires higher than the head clearance had to be done at night when C-Runway is closed, as the site was under the flight route of C-Runway. Due to its constraints, construction must be carried out 24 hours a day, 365 days a year. The offshore end of D-runway required an elevation of more than A.P. (Arakawa Peil[1]) +17.1m as the airplanes had to pass over large ships navigating nearby.

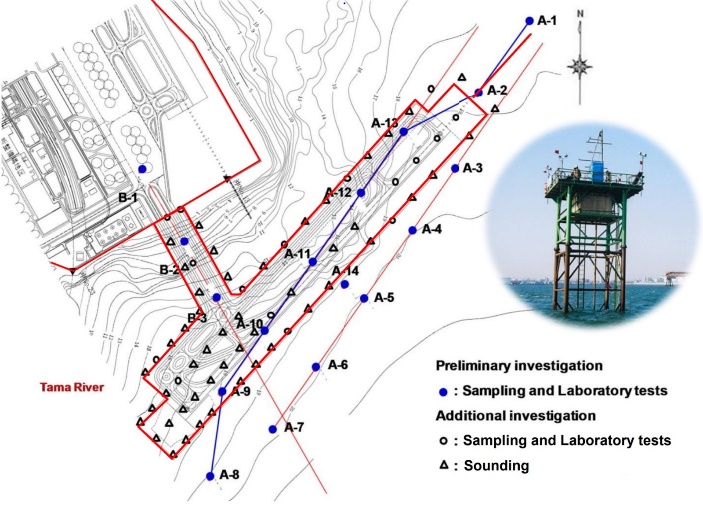

Site Investigation

Boring and sampling investigations were carried out to A.P. -100m, where boreholes A1-A14 were located at the main structure of D-Runway and boreholes B1-B3 were located at the taxiways. Figure 3 shows the locations of the boreholes on the construction site.

|

|

|

Fig. 3: Locations of Boreholes (Watabe & Noguchi, 2011) |

The soils were classified as Alluvial for soils that were above A.P. -35m, and Diluvial for soils that were below A.P. -35m. A Standard Penetration Test (SPT) was conducted to estimate the relative density of soils and approximate shear strength parameters. Table 2. Shows the correlation between the N Value, Soil Packing and Density (“Standard Penetration Test – Geotechdata.info”, 2016).

|

N-Value |

Soil Packing |

Relative Density (%) |

|

<4 |

Very Loose |

<20 |

|

4-10 |

Loose |

20-40 |

|

10-30 |

Compact |

40-60 |

|

30-50 |

Dense |

60-80 |

|

>50 |

Very Dense |

>80 |

|

Table 2: Correlation between N-Value, Soil Packing and Density (adapted from “Standard Penetration Test – Geotechdata.info”, 2016) |

||

It was found that the alluvial clay that exists at a depth of 33m below seabed elevation is a soft clay stratum with an N value of 0. Below this depth, alternate layers of diluvial sand and diluvial clay exists with N values of 20 to 40. At depths 55 to 60m, sand and gravel layers are firm with N values exceeding 50. The geological cross-section was identified and classified into 5 layers with names that indicates the geological history: Y (Yurakucho Layer), Na (Nanano Layer), To (Tokyo Layer) and Ed (Edogawa Layer). Clay, sand and gravel were expressed as c, s and g respectively. Layer 1 was a soft clay deposit that had to be stabilized for construction; Layer 2 was a low plastic silty clay with a Plastic Index (Ip) of about 15. Because of the large coefficient of consolidation, layer 2 does not require ground improvement technology during construction. Layer 3 consists of alternating gravel, sand and clay layers. The undrained shear strength and consolidation yield stress was estimated based on the depth profile of layer 2. It was noted that there was a weak region that consisted of materials from layer 2. Both layers 4 and 5 were used as bearing layers. Figure 4 summarizes the geological layers and the technology used.

Reclamation section

Due to time and cost constraints, it was not a viable option to strengthen the thick soft clay deposit before reclamation. A mild sloped rubble mound seawall was used as it has the flexibility to allow settlement of the ground in conjunction with a sand compaction pile (SCP) method to enhance the soft clay layer. As the reclamation height behind the seawall was massive, lightweight soils that were made using dredged clay combined with cement was cast behind the seawall to improve the stability of the ground. The sand drainage (SD) method was used to improve the soil in the reclamation area. As a result of the tight construction period, construction had to proceed when the degree of saturation had just reached 50%, hence controlling the stability and settlement were of paramount importance. Various devices and equipment were installed in six major sections along the seawall to allow constant control or adjustments of filling work. In every work phase, radioisotope (RI) cone penetration tests were used to measure the strength of ground and other significant factors. Mizuno et al. (2012) created a consolidation settlement prediction system that consists of a stress history database, geotechnical condition database and a FEM analysis solver. The factor of safety was constantly calculated to monitor the stability of the seawall. Clayey deposits had a factor of safety of 1.3 and sandy deposits had a factor of safety of 1.2. If the factors were calculated to be below the specified value, the filling operation was halted until the water pressure had sufficiently dissipated with a resultant gain in strength.

Piled Pier Section

A total of 198 units of prefabricated steel jacket structures, with dimensions of 63x45x32 metres, weighing 1300t, were introduced for the main body of D-Runway. A total of 1188 steel pipe piles, measuring 1600mm in diameter and 90m in length, were driven into the bearing layers of the ground. The jacket units were then put into place onto the pipe piles by grouting (Noguchi et al., 2012).

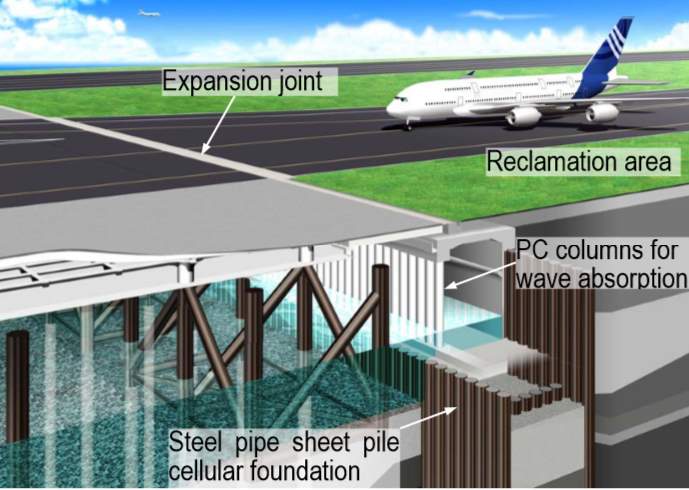

Joint Section

The joint section is simply where the piled pier section and reclamation section meets. Steel pipe piles were used as well-foundation for the joint section as it had a good track record in bridge foundations and abutments (Pipinato, 2016). It consisted of 24 rectangular cells that has an outer envelope of two parallel and 25 orthogonal steel pipe sheet piles. The steel pipes that measures 1.6m in diameter, were driven down in two rows perpendicular to the runway as well as the direction parallel to the runway to a depth of 75m. Lightweight backfill was used to reduce the lateral earth pressure, consolidation settlement, and lateral soil movement (Watabe & Noguchi, 2011, Mizukami & Matsunaga, 2016).

Precast Concrete

Two types of precast concrete slabs were used in the construction of D-Runway: Precast Concrete Slab (PCa) and Ultra-high-strength fibre-reinforced concrete slab (UFC). The UFC slabs were used extensively during the construction of the runway with just under 7000 UFC slabs being used. The UFC slabs were placed on runway strips and overruns with an area of 200,000m2, where heavy loads are seldom experienced, unless in emergencies. It has a compressive strength of 180N/mm2, and it is significantly lighter than ordinary concrete slabs. Hence, it can reduce the weight of the structure of 60%, which in turn decreases the horizontal force due to seismic loading. The permeability of UFC is significantly lesser than ordinary concrete by a factor of 100, which dramatically decreases the penetration of saltwater. This increases the durability of the slab. PCa were installed in the remaining 310,000m2 of the 500,000m2 jacket structure, which consisted of the runway and taxiways. The design strength of the slab was 50N/mm2. Expansive concrete was filled between neighbouring PCa slabs to securely connect the slabs for the airfield to behave as a huge flat plane without joints. Precast Prestressed Concrete columns, measuring 1,200mm in diameter, were installed together with the steel pipe well foundation with 600mm slits to create a slit type seawall. This reduces the energy of the waves that passes through the seawall (Niihara et al. 2007, Mizukami & Matsunaga, 2016). Figure 5 shows the hybrid structure that combines the reclaimed area to the Piled Pier Section.

|

|

|

Fig. 5: Hybrid Runway (Watabe, 2013) |

5. CONCLUSION

Airports play a major part of a countries economy as they help transport goods and people for a country, from an infrastructure point of view they are high value assets as they are the first point of contact for disaster relief. When developing or maintaining an airport it is important to take several things into consideration and assess the local conditions to ensure they are suitable for the design before implementing the designs. A decline in airport runway quality is noticed with exceeding demands are noticed in airport traffic. With airport runways and taxiways deuterating in quality from external factors such an increased traffic and load, as well as environmental factors, it is important to understand the criteria set for pavements to which they are graded against.

Find Out How UKEssays.com Can Help You!

Our academic experts are ready and waiting to assist with any writing project you may have. From simple essay plans, through to full dissertations, you can guarantee we have a service perfectly matched to your needs.

View our academic writing services

This paper aims to provide better understanding of design considerations for heavy industrial and airport pavements, the paper focuses primarily on airport runway pavements and refers to the industrial use of pavements briefly to provide a better understanding of the design purpose of pavements. This paper explores several different types of airports as well as multiple pavement designs that are implemented and provides understanding on how to assess the proposed design for optimal results. A brief comparison is made between rigid and flexible pavements to provide knowledge on suitable implementation of said pavement based on soil and surrounding materials, with common distresses that can be seen in the pavements.

A criterion for common considerations for airport pavement designs was developed by the team based on knowledge gained when undertaking research in pavements implemented in airport runways and taxiways. The considerations range from planning, implementing and renovating with any maintenance and upkeep in mind. Providing a basic understanding on how to select and implement a proposed airport design with any necessary amendments.

A case study was undertaken on the Tokyo Haneda Airport to understand the different geotechnical challenges it has when constructing a hybrid structure for its runway. The airport was completed on schedule and went operational in 21 October 2010. Due to its unique structure, D-Runway is said to be a high-tech geotechnical museum. By identifying the 5 layers during ground investigations, it was found that Layer 1 had to be stabilized for construction, Layer 2 did not require any ground improvement technology due to the large coefficient of consolidation. Properties of Layer 3 were derived from extrapolation from depth profile of Layer 2, and Layer 4 and 5 were able to be bearing layers. Because of the adequate site investigation and understanding on the properties of the soil, it has remained in service even though it experienced a 9.0-9.1 magnitude earthquake in 11 March 2011 with no major damages. Lightweight Backfill helped to reduce the lateral earth pressure, consolidation settlement, and lateral soil movement, which helped shorten the working period and save on ground improvement costs. Sand Drainage method was used to improve the upper soft subsoil layer to accelerate consolidation. Various existing technologies was applied in the construction of the runway as well as developing new materials to construct D-Runway in a safe, rapid and economical way.

6. REFERENCES

- Ahmad Zaini, A., A. Aziz, M., Kassim, K., & Mustafa, K. (2016). A Review On Crack Relief Layer In Airport Runway. Jurnal Teknologi, 78(7-2). Doi: 10.11113/jt.v78.9477

- Airport Pavements 2017, ‘Airport Pavements’, in R. B. Mallick & T El-Korchi (eds), Pavement Engineering: Principles and Practice, Third Edition, CRC Press LLC, pp. 619-654.

- Airport Pavement Design and Evaluation. (2016). Retrieved 6 October 2019, from https://www.faa.gov/documentLibrary/media/Advisory_Circular/150-5320-6F.pdf

- Chapter III – Planning Considerations | Airport Passenger Terminal Planning and Design, Volume 1: Guidebook. (n.d.). Retrieved from https://www.nap.edu/read/22964/chapter/4

- Chapter 4 Landside Technologies and other Airport Infrastructure. (2019). Retrieved 16 October 2019, from http://web.engr.oregonstate.edu/~hunterzk/other/primer/ch4.html

- Deilami, S., & White, G. (2018). Review Of Reflective Cracking Mechanisms And Mitigations For Airport Pavements.

- FAA. (2016). Airport Pavement Design and Evaluation. U.S. Department of Transportation Federal Aviation Administration.

- Haneda Airport. Retrieved 12 October 2019, from https://www.japan.travel/en/spot/1652/

- Jaskula, P., & Judycki, J. (2016). Durability of Asphalt Concrete Subjected to Deteriorating Effects of Water and Frost. Journal of Performance of Constructed Facilities, 30(1), C4014004. doi:10.1061/(asce)cf.1943-5509.0000645

- Mehta, Y., Cleary, D., & Ali, A. (2017). Field cracking performance of airfield rigid pavements. Journal Of Traffic And Transportation Engineering (English Edition), 4(4), 380-387. doi: 10.1016/j.jtte.2017.05.010

- Mizukami, J., & Matsunaga, Y. (2016). Construction of D-Runway at Tokyo International Airport. Japanese Geotechnical Society Special Publication, 2(2), 122-134. doi: 10.3208/jgssp.esd-kl-4

- Mizuno, K., Watabe, Y., Kobayashi, M., Noguchi, T., Aoki, Y., Yamamoto, T., & Takahashi, M. (2012). Long-Term Consolidation Settlement Prediction of D-Runway in Tokyo International Airport. Journal Of The Society Of Materials Science, Japan, 61(1), 78-84. doi: 10.2472/jsms.61.78

- Niihara, Y., Hayashi, S., Koshiishi, M., & Hashimoto, M. (2007), PC Structures Used in the New Runway of Haneda Airport, Tokyo International Airport D Runway Construction Project, pp. 165-168.

- Noguchi, T., Horikoshi, K., Shimizu, M., Niihara, Y., & Okutsu, N. (2012). Construction of new runway from pier-type jacket structures with large-diameter long steel pipepiles. Soils And Foundations, 52(6), 1073-1092. doi: 10.1016/j.sandf.2012.11.022

- Pipinato, A. (2016). Innovative bridge design handbook (pp. 615-653). Butterworth-Heinemann.

- Runway construction – Designing Buildings Wiki. (2019). Retrieved 16 October 2019, from https://www.designingbuildings.co.uk/wiki/Runway_construction

- Smith, G. (2011). Retrieved from https://www.burnsmcd.com/insightsnews/publications/aviation-special-report/2011

- Standard Penetration Test – Geotechdata.info. (2016). Retrieved 12 October 2019, from http://www.geotechdata.info/geotest/standard-penetration-test.html

- Watabe, Y. (2013). Geotechnical challenges in the D-runway (4th runway) project of Tokyo Haneda Airport. Presentation.

- Watabe, Y., & Noguchi, T. (2011). Site-Investigation And Geotechnical Design Of D-Runway Construction In Tokyo Haneda Airport. Soils And Foundations, 51(6), 1003-1018. doi: 10.3208/sandf.51.1003

- White, G. (2018). State of the art: Asphalt for airport pavement surfacing. International Journal Of Pavement Research And Technology, 11(1), 77-98. doi: 10.1016/j.ijprt.2017.07.008

[1] Base Level of the Ara River

Cite This Work

To export a reference to this article please select a referencing style below: