(a) Introduction

3.1 This narrative is based on my final year project, completed as a part of my bachelor’s degree in Mechanical Engineering at Rajiv Gandhi College of Engineering (Anna University affiliated) Tamil Nadu, India. The project on “Job offset in a CNC milling machine” was carried out at Tractors and Farm Equipment Private Limited (TAFE), Tamil Nadu, India and was performed between the months of Jan, 2014 to April, 2014.

(b) Background

- The final year project is a mandatory unit for the bachelor of engineering degree which has to be completed in a group of four as a part of the curriculum. I did this along with three others who were with me during the last semester of my degree. During the course of the project, I presented several presentations and seminars according to the guidelines of Anna University. The project was done in order to reduce the defects during production at Tractors and Farm Equipment Limited (TAFE).

- With increasing competition in all fields and industries, the market demands zero defect products. In order to facilitate this, I implemented the ‘poka-yoke’ scheme to reduce the production defects by using simple cost effective techniques. In a machine cell, the quality of machining should be inspected after each machining. After every machining, the quality of product gets reduced due to the formation of the burr which further leads to an offset in the next job. This offset causes the quality loss in machining and hence the product dimensions have a slight deviation from the actual dimension.

- The nature of my work was to design a pneumatic system which alerts the machine operator if an offset was detected. The project was supervised under Mr. Manoj Kumar Roy, the assistant professor in the department of Mechanical Engineering at Rajiv Gandhi College of Engineering. I also did extensive literature research on total quality management techniques and came up with this poka-yoke strategy for mistake proofing to prevent defects.

- Some of the core principle duties of this project incorporated the following:

- During the course of the project, I attended meetings with my project coordinator and my team mates to discuss the progress of our project.

- I also coordinated several formal and informal group meeting with my group members to discuss on any problems encountered during the course of the project.

- I presented seminars and reports as a part of my bachelor’s degree curriculum.

- I referred to a number of papers to collect information on the poka-yoke scheme.

- I performed a plant quality analysis to analyze the number of product defects in a particular year.

- I prepared a report on the observations made by each member of the team.

- The ever increasing production demands for a zero defect product quality. This has given rise to various techniques for quality management. Among different techniques, I selected the poka-yoke technique which is a Japanese improvement strategy for mistake-proofing to prevent defects from arising during production processes. I selected this technique because of its simplicity and efficiency in a cost efficient manner.

- I performed an analysis to determine the major causes of defects in order to device ways to reduce or eliminate them. I found that, the errors are often due to the misunderstanding, incorrect identification, could be good intentions but improperly implemented such as processing errors, error in setting up the work piece, assembly omissions, a wrong part was included, wrong work piece, errors in preparation of tools, equipment maintenance errors, operational errors, dimensional errors, fixtures, blades. etc. All these errors was prevented by the application of the poka-yoke technique.

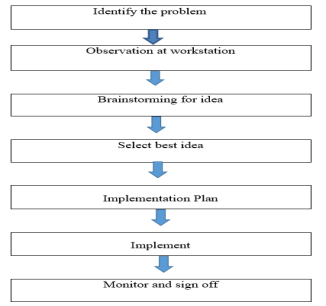

- I prepared a flow chart (figure 1) for the methodology to be followed for mistake proofing. I referred to a number of papers to learn more about the concept of poka-yoke. I found out that poka-yoke can be classified into three types as shutdown poka-yoke, warning poka-yoke and control poka-yoke. I analyzed the sales profile of the company for its various products: transmission casing, front axle line, centre housing line and differential casing line.

Figure 1: Methodology of mistake proofing

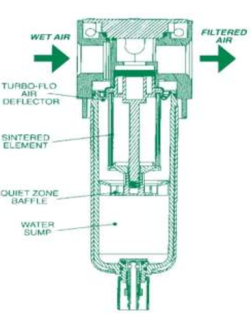

- I applied the poka-yoke technique for the elimination of errors in a CNC milling, drilling and boring machines. A milling machine is a fully computer controlled vertical mill with the spindle moving vertically along the Z axis. The first equipment that I designed for the elimination of errors in the CNC milling machine was the pneumatic air filter.

Figure 2: Pneumatic air filter

- In the compressed air system, hard particles tends to damage the equipment and piping. The result is damage to the system and more particles are generated. The pneumatic air filter helps eliminate these impurities. The next equipment which I suggested for the machine was the mist collector. The mist collector works on mechanism of inertial impaction, interception and Brownian diffusion. I also included the use of an air pressure regulator which is a valve that automatically cuts off the flow of a liquid or gas at a certain pressure.

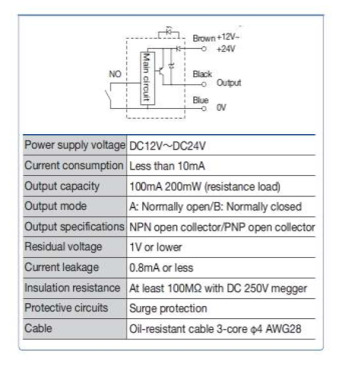

- I designed an air micro switch which is a switching device used for detecting the displacement of work piece and is kept on a machine while machining. It applies the principle of air micrometers, and can detect the seating of the objects without contact. It is designed in such a way to work in any harsh conditions, so that it can be placed inside the drilling machine. The back pressure that is received from the sensed components was allowed to hit a diaphragm which then deforms to give the pressure output. If the pressure received was large enough to move the air switch upwards, it closed the circuit and hence the operator could be alerted. However, the output current that was produced by the sensor was very low and hence to amplify the output signal, I placed a PNP transistor inside the sensor. The transistor amplifies the current and sends it to the output.

Figure 3: Circuit diagram and specification of PNP transistor

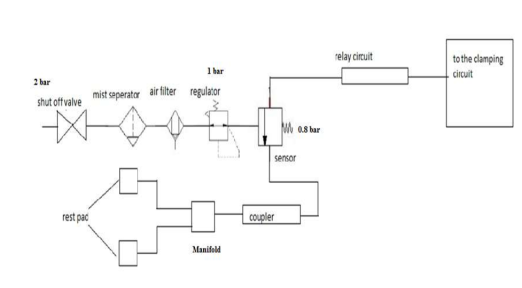

Similarly, pneumatic coupler, pneumatic manifold, rest pad and relay circuits were also added.

Figure 4: Schematic of the components used in the machine

- The project was mainly intended to alert the machine operator if a job was not seated correctly on the CNC machine. The clamps that hold the job in the CNC milling machine would not work unless the proper seating takes place. The minimal gap allowed was 10 microns. Beyond that the relay switches off the clamping circuit. The shut off valve cuts off the pneumatic circuit in case of any emergencies. The mist separator was used to absorb the moisture content present in the air. The purpose of air filter was to remove the impurities present in the air which could cause damage to the machine during operation. The air pressure is regulated by the regulator passing through the air filter. This prevents damage to the machine. The air micro switch acts as the sensor. If the pressure that was received from the device was not sufficient enough, then the clamping circuit would be disengaged. Pneumatic coupler connects the air supply with the pneumatic manifold. The purpose of the manifold was to divide the supply of air to multiple channels. Rest pads or Butt pads are the provisions provided on the machine for the job to be seated.

- The main objective of this project was to provide mistake proofing to a CNC machine. I was able to execute this by making changes to the existing horizontal milling machine. I analyzed the defective product after the implementation of the project. The implementation of the project leads to the decrease in rejection of the machined products by 3% and have considerably increased the production rate. Finally, a master report was submitted to our department head. I also underwent an oral viva voce examination where I had to present my part of the project briefly and answered questions about various aspects of the project.

- This project in my engineering career helped me comprehend valuable principles of working together as a team and presented me the opportunity to understand and implement my theoretical knowledge into practice. I understood the importance of working as team and the need to step up as a leader when necessary. I gained profound knowledge in total quality management, seminars and presentations which boosted my confidence during the course of the project. The project was completed in time and well within budget. It also provided me a great exposure with company personnel and I benefitted a great deal from the interactions with company superiors.

Cite This Work

To export a reference to this article please select a referencing style below: