Abstract

Today this problem related to wastage material increased day by day it become a major problem for us. To reduce the ratio of garbage our project will help and it can reduce the ratio of wastage in that kind of area where more rubbish like garden, playground, park and beaches. Our project working with the help of axle, conveyor, sensor and two main motor which run our prototype. The robot will work in such a way when the robot will start it will start working according to its programming and move around the particular space and when any obstacle or polythene comes into its way then the robot perform its works according to its programming and pickup that thing and put it inside the bin. Another thing which is good in our project that is automatic process to collect the garbage. Our project reduces the manpower to achieve the outcomes from this project.

Introduction

Polythene problem become a big issue for this world because it damages the natural thing with slow death rate that’s why polythene is banned in some country. New Zealand also faced the problem of plastic wastage in every year New Zealand produce 2 lac tones of plastic due it increasing the number of plastic wastage. The main purpose of our project is reduce the wastage of plastic. This project shows the automatic process and collecting way.

Overview

Literature review

I read many literature review regarding this project but related to conveyor and movement of axle I find these which below the paragraph. Develop and fabricate the conveyor belt which run with the help of secondary motor as well roller also. Movement of axle according to given dimension that is also part of programing and below the table of this paragraph which shows the research on this project and development in project time to time.

Table 1 shows the different literature reviews of different projects

|

Project |

Manufacturer or developer |

Principle |

|

Prevention and reduction of plastic waste in automatic procedure |

Alexis baltazar y jimenez |

To make movement of tyres with less friction and easily turning functions |

|

Automatic garbage separation robot |

Saravana Kannan g, sasi kumar s, ragavan r, balkrishana m |

Conveyor belt was used but it was not getting proper tension so I will use chain instead of belt |

|

Design and implementation of metallic waste collection robot |

Hesham alsahafi, majed alamleky |

Conveyor motor needs re[lacement instead of stepper motor to dc motor |

|

Automatic garbage collector |

Mahendra urf aventro ul wakiff |

Automation of conveyor |

Automatic mini beach cleaner

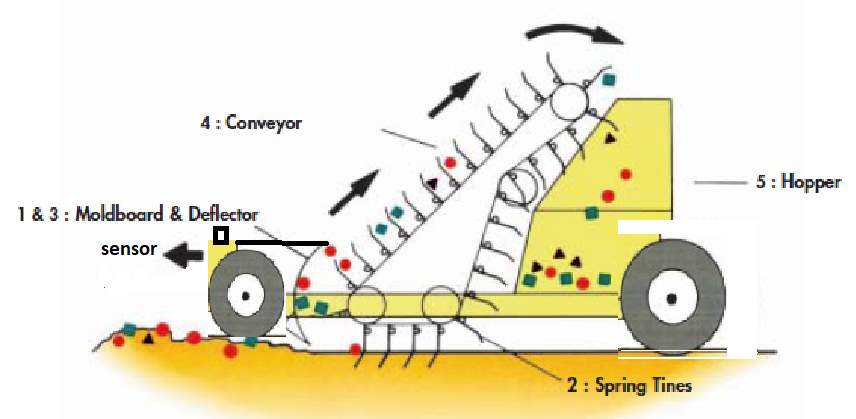

This kind of beach cleaner small in size but powered by tractor and in this cleaner conveyor belt was not used to pick up the polythene from ground level and its width is around 1200mm while height was 850 mm and 350 was its weight. Working depth of this cleaner was up to 15 cm. its totally made by iron material which is very solid. Another thing which is limitation of this cleaner is its working on the dry beaches.

Figure 1 mini beach cleaner(mini cleaner, n.d.)

Automatic garbage separation robot

To make the environment eco-friendly automatic garbage collector robot is helping. The main purpose of this robot it separates the garbage into the bin because there is a one big dustbin used for separation. There are many technologies used for collecting the garbage before this robot. To run this robot 60 rpm motor are used and it has a two arm which work according to its movement. The working principle of this robot it working under the random movement of vehicle and if any scrap is detecting in the path of its then ultrasonic sensor is sense that objective and after that take it then put in the bin.

Figure 2 garbage separation robot(grabage robot, n.d.)

Project scope

The plan and create of programmed polythene gatherer is intended to expel the loss from the earth and make the environment around the human great and unadulterated through which the human can endure effectively and with less number of infections. Presently a day’s various robots are developing which are attempting to gather the trash yet these robots did not perform their function admirably and has different disadvantages which additionally incorporates once in a while wounds to the human. Furthermore, the labor is additionally used to gather the garbage which is such a misuse of money and human life, in light of the fact that wastage can cause distinctive risky ailments which can come inside the come body during the contact with the human hands. Our project will take many advantage in the future because it is very helpful as well as it can reduce the human effort that’s why it will become demandable thing in upcoming years.

- Sensor will control the robot which will give more efficiency

- Four-wheel drive robot which can run in both forward and backward direction

- More rubbish from the area will remove with the collector movement

- Reduction in the manpower

- Automatic process

Project objective (overall)

- Easy to operate

- Eco friendly

- Save energy

- Apart from polythene it can take rubber, glass and other stuff

- Its working automated

Individual objective

our project has many objectives which divided into group member my objectives is given below;

-To study, select, and design of the axle of the wheel of developed prototype.

– To study, design, and belt of conveyor of developed prototype.

– To develop the moment of roller for the conveyor system of developed prototype.

– To model and program of secondary motor to run the developed collector.

– To develop the code of the automatic process of conveyor system.

Purpose of conveyor

– To reduce the human effort

– To reduce the accident with the help of sensor and monitoring

– To reduce time of material handling

– To minimize cost of material handling

– Lower investment in process inventory

According to individual objective the purpose of conveyor is to take the rubbish from ground floor with the help of teeth and it will run by motor. It is basically wide range belt which run rotary type with the help of driven motor.

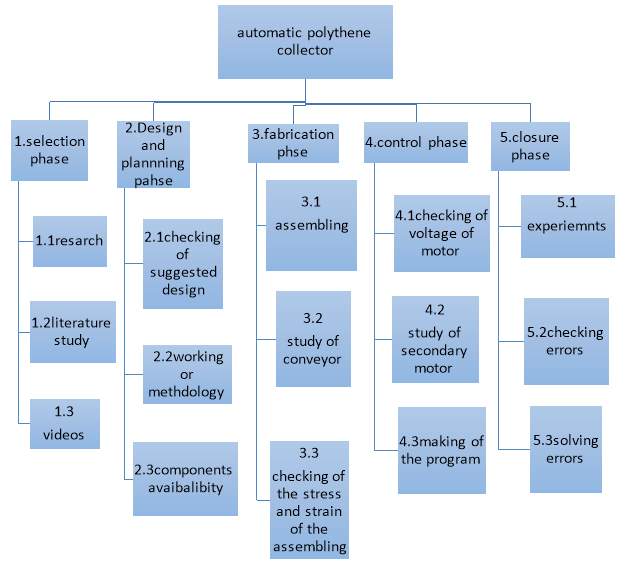

Work break down structure

Methodology

The structure and manufacture of automatic polythene authority is taking a shot at the straightforward system just it has some various connections which are interlink with each and perform their work according to one another. In the structure and fabricate of polythene authority various segments are utilized which will like sensors, motors, tires, teeth’s or so on. In this the camera or sensor will be introduced at the front of the machine which will consistently work the zone wherein this machine will connected and when the camera or sensor will detect any item or any trash than it will be offer direction to the fundamental engine and the principle engine will run the four tires towards that waste and next work is of the authority development component , when the machine will go towards the garbage than the teeth of the gatherer will gather that junk and will put that refuse inside that canister, which is joined to the frame of the machine. The casing and authority will design in such a manner the teeth will spin around the gatherer instrument and these teeth’s will be change so that they won’t stuck into the junk container while placing the garbage into the receptacle.

Figure 3 methodology of project(automatic cleaner, n.d.)

Figure 4 suggested design of the project(automatic polythene colletctor, n.d.)

Requirement of Component

- Dc motor

- Conveyor

- Wheels

- Sensor

- Teeth

- Bin for rubbish

bill of the material

|

Components |

cost |

Website name |

|

dc motr |

288 nzd |

|

|

Collector frame Metal frames Nuts and bolts |

||

|

48nzd |

www. Banneerbuznz.com |

|

|

10 nzd per piece |

Bunning warehouse.co.nz |

|

|

Assumed Teethes of less than 90 degree |

10nzd per piece |

|

|

Bin for rubbish |

50 nzd |

Bunning warehouse.co.nz |

|

Tires |

20nzd |

Richmond.co.nz |

|

Total |

520nzd |

|

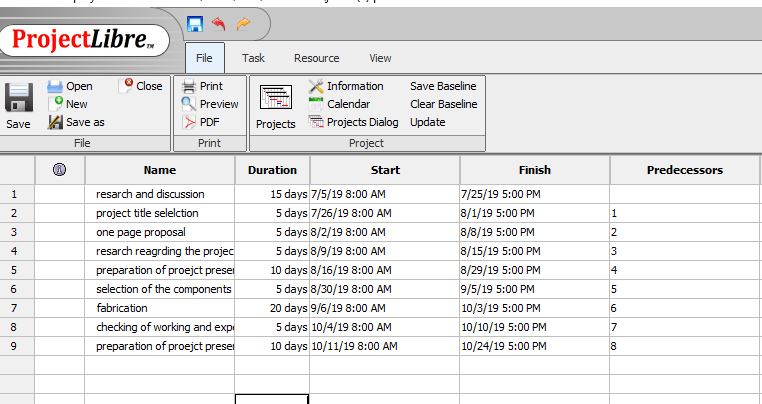

Project plan and schedule

Fig- Gantt chart

References

- automatic cleaner. (n.d.). Retrieved from https://www.google.com/search?q=methodology+of+automatic+plastic+collector&rlz=1C1CHZL_enNZ825NZ826&source=lnms&tbm=isch&sa=X&ved=0ahUKEwjE6IHl06nkAhVXYysKHR50AwgQ_AUIESgB#imgrc=AKuDITZWosMWHM:

- automatic polythene colletctor. (n.d.). Retrieved from https://www.google.com/search?q=automatic+beach+cleaner&rlz=1C1CHZL_enNZ825NZ826&sxsrf=ACYBGNQMbs7cswMDzkNN9e0THi60hNk6dw:1568950871354&source=lnms&tbm=isch&sa=X&ved=0ahUKEwj4qO26vd7kAhXLeisKHc85Ai4Q_AUIEigB&biw=1242&bih=597#imgdii=naIL9-bxysq7bM:&imgrc=X

- grabage robot. (n.d.). Retrieved from https://www.google.com/search?q=Saravana+Kannan+G,+Sasi+Kumar+S,+Ragavan+R,+Balakrishnan+M,+%E2%80%9CAutomatic+Garbage+Separation+Robot+Using+Image+Processing+Technique%E2%80%9D,+International+Journal+of+Scientific+and+Research+Publications,+Volume+6,+Iss

- mini cleaner. (n.d.). Retrieved from https://www.google.com/search?q=automatic+beach+cleaner&rlz=1C1CHZL_enNZ825NZ826&sxsrf=ACYBGNRJ7mhuOZKy2QioXgdB-xYpm2KOjw:1568938325148&source=lnms&tbm=isch&sa=X&ved=0ahUKEwit4q3cjt7kAhUTWX0KHdWPBE4Q_AUIEigB&biw=1242&bih=597#imgrc=u4RRJi0CatCscM:

Cite This Work

To export a reference to this article please select a referencing style below: