Topic: What are the different types of reinforcement for soil?

- Introduction | What is soil reinforcement

In essence, soil reinforcement is a technique which is commonly used to improve the strength and stiffness of soil by utilising geo-engineering methods. This allows the soil to resist more load. Many years ago, natural fibres were applied to reinforce soils, however this outdated technique did not produce a high yield and required ample time for the soil to recover.

Soil is reinforced and restored through the distribution of minerals and soil nutrients. In geotechnical engineering, reinforcement of soil is vital and necessary in lands where erosion is high. Soil reinforcement techniques is commonly used in area with soft soil as it doesn’t provide sufficient support to any building/ construction. These types of soil are highly susceptible to numerous natural and environmental factors such as poor shear strength, high compressibility and temperature changes.

- Brief History of Soil reinforcement:

The concept of soil reinforcement was recognised more than 5000 years ago. Soil reinforcement consisted of mixing straw with mud, with woven reeds and using branches and other plant fibres to improve the overall strength and capacity to support greater loads.

There are numerous examples of reinforcements for soils which date back to the construction of the Great Wall of China (using branches of trees as tensile elements). In modern times, the concepts and principles of soil reinforcement was first developed by Henri Vidal. He showcased that introducing reinforcing elements in a soil mass increases the shear resistance of that medium.

Since Vidal’s discoveries, nearly 4000 structures in more than 37 countries have been built using his concepts of soil reinforcements.

- How is it done?

Soil is reinforced by placing tensile elements in the soil to improve its natural strength and stability. This is accomplished by comprising reinforcement elements with surfaces in the aggregate and sub-base of soil mass. When pressure is applied on the soil mass, it causes a strain on the reinforcement, creating a tensile load which can now resist soil movement and provide additional support. By doing this, soil is reinforced and provides much greater shear strength than the soil mass alone.

LABEL ALL DIAGRAMS AND PICS!

- Materials and Types of soil reinforcement

There are 3 main materials which are commonly used in the construction of reinforced soil:

- Soil or fill matrix

- Reinforcement or anchor system

- Geosynthetics

These materials are used based on the soil properties.

- Soil or fill matrix

The shear properties of soil can be enhanced as theoretically any soils from earth can be used. Usually the soil used is well graded cohesionless or good cohesive frictional soils, however in many instances pure cohesive soils have been successfully used.

There are a few advantages from using cohesionless soil:

- They are stable

- Free draining

- Not susceptible to frost

- Relatively noncorrosive to reinforcing elements

However, the main disadvantage is the cost, as a convenient compromise between the benefits from cohesionless soils and economic advantages from cohesive soils makes cohesive frictional soils to be preferred.

- Reinforcement or anchor system

A wide range of materials such as steel, glass, concrete, fibre, wood, aluminium, rubber and thermoplastics can be utilised as reinforcing agents. These reinforcements can have the structural forms of strips, anchors, planks, material chain, rope or a combination of these.

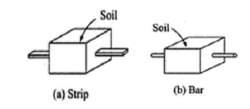

Strips:

These are flexible linear elements, having their thickness less than their breadth. They can be comprised of copper, polymers, aluminium, glass fibre or bamboo. Galvanised or coated steel strips are paired with either plain or with projects to increase the friction between reinforcement and fill.

These are flexible linear elements, having their thickness less than their breadth. They can be comprised of copper, polymers, aluminium, glass fibre or bamboo. Galvanised or coated steel strips are paired with either plain or with projects to increase the friction between reinforcement and fill.

Grids:

Grids:

Grids are also used as reinforcements. They consist of steel (in the form of plain or galvanised weld mesh/ expanded metal).

Sheet: This reinforcement may be formed from fabric or metals such as galvanised steel sheet and expanded metals.

Similarly, composite reinforcements can be developed by collating different materials and forms to suit the soil conditions. The principal requirements of reinforcing materials are their strength, stability, durability, handling, coefficient of friction and soil compatibility. Factors such as cost and availability are also accounted for.

- Geosynthetics

Geosynthetics refers to man made products, they are flexible in nature and planar (sheet like). These materials are manufactured from synthetic polymers and sometimes are comprised of natural materials. These are vital in the engineering field as they are used as filters, drains, reinforcements, barriers and have erosion control applications.

Geotextiles are a permeable synthetic textile material; this is generally produced from polyester or polypropylene polymers. These are used to increase the overall soil strength, stability, prevent erosion and aid in drainage. A range of geotextiles can be produced using various manufacturing processes and different polymers, they can be woven or non-woven. Woven geotextiles are made by interlacing 2 or more fibres (at right angles). Non-woven are produced by mechanical bonding or needle punching.

Geogrids is a geosynthetic material with a mesh like structure which has square or rectangular openings that are larger than the thickness of the ribs. The thickness of ribs ranges from 5 to 15mm, and the mass varies from 200 to 1500gms.

Likewise, geonets share many similarities to geogrids however they have tinner member sand angular apertures, and instead of having square or rectangular openings they consist of parallelograms.

- Soil Reinforcement Techniques

Soil reinforcement techniques can be categorised into two major groups, Insitu soil reinforcement and Constructed soil reinforcement. Insitu reinforcement is a technique where reinforcements are placed in undistributed soil to form a reinforced soil structure. This include the technique of soil nailing and soil dowelling.

Soil Nailing

Soil nailing is a technique commonly used to reinforce and strengthen the ground adjacent to an excavation by installing closely spaced steel bars or “nails”, as construction commences from top down. Vertical or steeply inclined cuts can be made for open excavation using rigid soil nails as reinforcement. These cuts are also referred to as nailed soil walls. The facing of the walls is usually in the form of a wire-mesh reinforced shot Crete panels, although metal plates and other panels may also be utilised. Soil nails are installed at 20 to 25-degree inclinations horizontally to the ground, this is to avoid intercepting underground utilities. Inclinations is reduced to 10 – 15 degrees as we go deeper into cut.

Soil nailing is an effective and economical method of constructing retaining wall for excavation support, bridge abutments, highways etc. The nails are subjected to tension compression, shear and bending moment.

Favourable soil condition:

- Stiff to hard fine grained soil

- Dense to very dense granular soils with apparent cohesion

- Weathered rock with no weakness planes and glacial soils

Advantages of Soil Nailing:

- Given right soil conditions, a rapid and economical means of constructing earth retention support systems and retaining walls.

- Retaining walls are secured laterally into the soil, eliminating piles and foundation footers.

- Shorter drill holes

- Grouting only once is required, thus saving time and labour

- This method is flexible and easily modified.

- Can be used for strengthening of either natural slope, natural or man-made cut slopes

Disadvantages:

- Generally larger lateral soil strain during removal of lateral support and ground surface cracking may appear

- Tendency of high ground loss due to drilling technique, especially at course grained soil

- Less suitable for course grained soil and soft clayey soil which have short self-support time and also soils susceptible to creeping

- Suitable for excavation above groundwater

Constructed soil reinforcement technique:

This technique involves reinforced soil structures with vertical face. The facings usually consist of prefabricated concrete or steel panels joined together by an interlocking mechanism. The soil is utilised as backfill in cases where the soil is granular with less than 15% fines to allow the development of large friction between the soil and reinforcement. The most often used reinforcement is steel strips as they have large tensile strength and low extensibility.

Find Out How UKEssays.com Can Help You!

Our academic experts are ready and waiting to assist with any writing project you may have. From simple essay plans, through to full dissertations, you can guarantee we have a service perfectly matched to your needs.

View our academic writing services

This method describes the technique where the reinforcement is placed at the same time as an imported and remoulded soil. These techniques are commonly knows as ‘bottom up process’ as they involve the placement of a fill and reinforcement simultaneously, these involve structures such as bridge abutments and soil embankments. The reinforcement required to carry out this process involve form of strips, grids or mats.

- Challenges in soil reinforcement:

Plans for soil reinforcement are always personalized according to the soil’s properties (texture, load bearing capacity etc.). As there is a wide variety of soils and load variations, many challenges may arise. These include but isn’t limited to:

Embankments on weak foundations:

The main challenge for embankments on weaker foundations such as airports near soft or sandy ground is to reinforce the soil and stabilise it.

Retaining walls:

Geotextiles are combined with different kinds of wall applications such as on-site fills to reinforce the supporting walls. Geotextile provides an alternative to traditional methods such as cast-in-place concrete structures for retaining walls.

Subgrade Stabilising:

For soft and organic soils, the tensile strength is low. The cost required for traditional land filling can be up to 50% higher than the cost of soil reinforcement with geotextiles. Geotextiles can be utilised to disperse the load uniformly within the soil and reduce the displacement of small soil particles.

Reinforcing Base Course:

By increasing tensile strength of granular base course material, the overall load bearing capacity of soft soil is improved. The use of geotextiles increases the tensile strength by increasing its load bearing capacity at the granular base structure. A grid is commonly used for this.

Steeping Slopes:

Layers of geotextiles are placed methodically on the land to steepen soil slopes. This achieves overall increase of tensile strength without the risks of soils sliding or rotating.

- Application of Soil Reinforcement

There are many applications of soil reinforcement, these consist of but isn’t limited to:

- Slope Failure repairs

Large and small landslides and failures of these natural slope occur often in areas where the environment call for repair of the slope to the original geometry, this may be due to technical or economical touristic attraction or artistic reasons. Geogrids allow using the same soil of the landslide to reinvent the slope, hence providing a solution instead of importing a soil with better mechanical characteristic which will have cost implications. An advantage of geogrids reinforced slope is that it can be easily vegetated to achieve seamless integration with the surrounding environment.

- Slope cutting repairs

The installation of underground structures such as pipelines often require creating a slope to protect valuable areas where authority imposes to repair the cutting to the original situation. This may result in geotechnical issues due to excavated soil being in lower mechanical characteristics than the original soil in the slope. Geogrids improve the stability of the soil and thus allowing the slope to be rebuilt without expensive methods.

- Steep slopes embankments and bunds

In many situations there is a shortage of space or fill material for construction of embankments and bunds with steep slopes. Geogrid reinforced soil structure provide a safe and economical solution which have the following application.

- Noise protection bunds along highways, railways etc.

- Blast protection embankments

- Increase of the available volume in exhausted landfills

- Constriction of embankment dams for solid or liquid impoundments

- Bridge abutments and wing walls

Bridge abutments and wing walls are often earth retaining structures that support the heaviest loads. Besides the high vertical and horizontal loads applied by the bridge deck, dynamic loads from traffic, and even seismic loads challenge the overall design. Soft soils, high water table and environment impacts contribute to further problems. Like other applications, geogrid reinforced soil structures provide strong yet flexible retaining structures. Bridge abutments and wing walls can be designed with intent to resist all anticipated loads with regards to safety and poor soil quality.

- Road and Railway embankments

Road and railway embankments are typically high and large structures, which require sizeable amount of fill soil and land. The cost of transporting this soil from quarries can be substantial and thus some alternatives are required, for example designing stepper slopes or using low quality soil fill.

References:

- https://www.sciencedirect.com/topics/engineering/soil-reinforcement

- http://www.ccr-mag.com/what-is-soil-reinforcement-and-how-is-it-done/

- https://www.ijera.com/papers/Vol6_issue8/Part-%202/D0608022531.pdf

- https://www.slideshare.net/anandu14793/soil-nailingsoil-reinforcement

- https://www.sciencedirect.com/science/article/abs/pii/S0950061811006763

- http://www.ijstm.com/images/short_pdf/1422589766_455.pdf

- https://study.com/academy/lesson/what-is-geotextile-fabric-definition-types.html

- https://slidesgo.com/theme/engineering-project-proposal

Cite This Work

To export a reference to this article please select a referencing style below: