Introduction: A spare wheel well, also called spare wheel baffle, is a recessed storage tub located in the trunk of the vehicle. As the name suggests, it houses the spare wheel and tyre, along with the lug wrench and wheel jack. Traditionally, it was made of stamped steel. [1] However, since this part has an important role in the vehicle’s rear structure and crash safety and is also prone to heavy corrosion due to the fact that its underside is always exposed to road elements. Manufacturers started using lighter materials- from aluminium to composite materials at present, reducing both ways in terms of weight and cost. [1]

Fig 1: AUDI A8 spare wheel well

In 2011, Audi presented the new Audi A8 luxury sedan, which debuted as the 1st user of short-glass pelletised thermoplastic material for the SWW. The wheel tub is manufactured using Durethan DP BKV 60 H2.0 EF, a 60% glass fibre reinforced PA 6 from German speciality chemicals company ‘LANXESS’. [1] The part is 100 cm x 85 cm x 32 cm in size and is manufactured by Dutch company ‘Vestalpine Plastics Solutions’ of Puttee, the Netherlands, using a gas-assisted injection moulding process. The tough tub weighs 9 kg/20 lb, yet it carries 70 kg/154 lb of additional components. [1] [2]

Get Help With Your Essay

If you need assistance with writing your essay, our professional essay writing service is here to help!

The tub is designed to carry 7 times its own weight. [1] It is able to carry the spare wheel and tyre, a car jack, an air suspension compressor and electronic housing of the battery. The battery is made secure by a perforated aluminium strip which is inserted while moulding the tub. Its dimensions are 849 mm * 130 mm * 289 mm and is mechanically bonded to the tub. [1] The SWW is also designed to reinforce the rear end of the vehicle, in case of head-on collisions and is securely bolted to the rear body frame. [1]

Fig 2: Different components of rear sub-frame; Part (1) indicates spare wheel well

The SWW is made in a single-stage injection-moulding process. Two important characteristics of this component are stiffness and strength. This is because the wheel tub has to support other accessories weighting up to 70 kgs, including the batteries and the protective aluminium strip.

Evolution of materials

- Steel

Steel has been the backbone of the automotive industry for manufacturing of the several components since the invention of automobiles. Different grades of steel are used for specific components according to the needs; The selection of steel primarily depends on the component, the strength required by it and how complex the component is to be able to be formed. [7] Some of the defining characteristics of automotive components are safety, energy absorption, ability to retain its shape in case of collisions, durability, etc. The AHSS family includes Dual Phase (DP), Complex-Phase (CP), Ferritic-Bainitic (FB), Martensitic (MS or MART), Transformation-Induced Plasticity (TRIP), Hot-Formed (HF), and Twinning-Induced Plasticity (TWIP).[6] [7] DP and TRIP steels show very good performance in crash-related regions due to their high energy-absorbing abilities. [6]

Fig 4: Comparison between conventional martensitic steel and TM steel

https://www.worldautosteel.org/steel-basics/automotive-steel-definitions/

Fig 5: Tensile Strength vs Elongation of AHSS grades

https://www.worldautosteel.org/steel-basics/automotive-steel-definitions/

- Disadvantages of Steel

Corrosion is an electrochemical reaction that appears in several forms, such as chemical corrosion and atmospheric corrosion, the latter of which is the most common form. [6] When acidic substances (including water, mud, sludge, etc) come in contact with metals, such as iron in the steel, rust begins to form. [6] [7] Since the underbelly of the SWW is in direct contact with the road, corrosion of the structure was inevitable. Also, the heavy weight reduces fuel economy and increased CO2 emissions. Combined with the heavy weight and durability issues, steel was rejected for making SWWs. [6]

- Aluminium

The next choice of metal for this purpose was aluminium. The potential of aluminium as a mass reduction material becomes obvious when looking at its specific weight (2.7 grams per cubic centimetre), which is less than half of that of iron (7.8 g/cm3) and copper (8.9 g/cm3). The SWW tub was made of a blend of aluminium and nickel, mainly casted by pouring molten aluminium into a mould. The resulting structure was lightweight, strong and ecological, giving better gas mileage and had better surface finish. The most favoured alloy of aluminium used in this case is Aluminium 5000 series. Typically used in applications in which corrosion resistance, high strength, good response to surface treatment, and good surface finish are required. 5000 series alloys respond well to gloss variations achieved by etching or brightening, and the final aesthetic finish obtained after anodising. They also offer excellent formability and good weldability.

Fig 6: Grades of Aluminium used in automobile applications

< https://www.worldautosteel.org/steel-basics/automotive-steel-definitions/>

- Disadvantages of Aluminium

Aluminium is susceptible to scratch and corrosion and less resistant to gravel, brake dust, dicers, etc. Unlike steel, aluminium is susceptible to peeling and pitting. Aluminium doesn’t contain iron or steel so it doesn’t rust – but it is prone to corrosion when exposed to weathering and atmospheric oxygen. [18]

The process of aluminium corrosion is known as oxidation. The resulting aluminium oxide is a thin, hard layer that actually protects the metal from further corrosion. Aluminium oxide appears as a powdery white or dull grey coating. As oxidation occurs, it hardens and creates a protective layer over the newly exposed areas of corroded aluminium. [18] The aluminium corrosion process is actually halted by oxidation – the metal won’t continue to deteriorate unless the aluminium oxide is removed. Unlike rust, which has a flaky, reddish appearance, aluminium oxidation cannot be easily chipped off the metal surface. Aluminium 5052, for example, is sometimes called The Hulk of aluminium alloys due to its durability and excellent corrosion resistance. Hence, due to limited manufacturability and high costs, auto-manufacturers started to look into composites. [2] [3]

- Composites

For SWW manufacturing, over the years, 4 different types of composites have been mainly experimented with. They are:

- Compression-moulded sheet moulding compound (SMC)

- Compression-moulded glass mat thermoplastic (GMT)

- Compression-moulded direct long-fibre thermoplastic (D-LFT)

- Injection-moulded pelletized long-fibre thermoplastic (I-LFT) [16]

Fig 7: Composition of SMC

<http://www.idicomposites.com/smc-bmc-overview.php>

Fig 11: Layers inside a GMT sheet

Composites are made of raw materials like Polypropylene (PP), Polyamides (PA), Thermoplastic polyesters (TPP), etc. which are made into a paste and mixed with chopped fibres of glass or carbon and finally, the paste is uniformly sandwiched between two sheets of plastic. [10] Depending on the type of reinforcing fibre and their lengths, composites are named accordingly. They are much easier to manufacture, especially for complex shapes. They are extremely lightweight when compared to metal counterparts, can be mass produced, recycled but most importantly, their physical and chemical characteristics rival those of steel and aluminium. Further characteristics are discussed in the benchmark analysis.

Fig 12: Comparison of long and short fibres

Fig 9: Physical properties of GMT

https://www.plasticomp.com/long-glass-fiber-reinforced/

Fig 10: Mechanical properties of GMT

<https://www.plasticomp.com/long-glass-fiber-reinforced/>

- Benchmarking Standards and Analysis

Benchmarking is the process of comparing existing performance data and analysis of a specific subject with a newly developed product/service. Benchmarking analysis is done by organizations as a market research to compare test data and adopt new materials and methods to improve overall quality of the product/service and simultaneously trying to reduce time of production and manufacturing costs. [19] This analysis is based on qualitative and quantitative properties to measure both aspects and these generate metric-based outcomes as well as best practices. The 4 stages of a typical benchmarking process are:

- Planning

- Analysis

- Action

- Review [19]

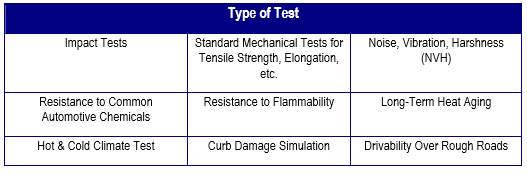

The SWW component is usually made of advanced high strength steel or aluminium or composites. The component has to pass through a number of tests to qualify for market sales. The primary requirement is that it should be able to provide structural rigidity to the rear sub-frame of the vehicle in case of a rear collision. [15] The SWW must be able to resist structural deformity, while also absorb the impact energy. This is the most important test required to pass by all European OEMS. Other important tests include reduction of noise, vibrations and harshness, different types of climates and weathers, toxicity, flammability, heat ageing, etc. [15] These tests check mechanical, electrical, optical, thermal and chemical properties of the raw material like the steel, aluminium or resin paste and also the laminates and thermoplastic materials Properties such as toughness, hardness, resistance to cracking, strength, cure, flame resistance, heat resistance, temperature limit, impact strength, viscoelasticity, ductility, tensile stress, compressive stress and shear stress are tested in general. [15]

Fig 19: General testing requirements for SWW applications in Europe regardless of material system used

To select a material for the SWW, the following properties are taken into account, along with its manufacturability and associated costs. These are:

- Stiffness

- Strength

- Durability

- Light-weighting

- Creep Resistance and Fatigue Endurance

- Dimensional Stability

- Noise and vibration damping

- Low manufacturing costs

- Recycling and Life Cycle Analysis

Based on the above parameters the benchmarking analysis has been done in this paper.

- Stiffness can be measured by the modulus of elasticity or Young’s modulus of that material. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

190-210 GPa |

70.3 GPa |

9.30 GPa |

6.30 GPa |

6 GPa |

- Ultimate tensile strength of the materials is compared. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

375 MPa |

228 MPa |

64 MPa |

140 MPa |

110 MPa |

- Durability of a material is defined by its ability to prevent corrosion or abrasion. Steel is vulnerable to rusting while aluminium is prone to abrasion by forming of oxides with water or air. Composites, overall, show a much higher resistance to corrosion due to their inert nature. [11] [12] [13] [14]

- Light-weight properties of the discussed materials can be compared by studying their respective densities. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

8.05 g/cc |

2.7 g/cc |

1.85 g/cc |

1.384 |

1.58 g/cc |

- Fatigue resistance can be measured by comparing the percentage of elongation at breaking point. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

5% |

12% |

1.8% |

2.7% |

2% |

- Dimensional stability may be defined by comparison of Poisson’s ratio of the different materials. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

0.28 |

0.33 |

0.3 |

0.36 GPa |

0.39 |

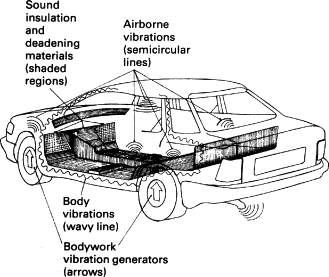

- Metals have shiny and reflective surfaces; hence they tend to reflect most of the sound waves. But composites are very good absorbents of noise and vibrations and implementing them tends to produce a much quieter ride. [11] [12] [13] [14]

Fig 17: Vibrations inside an automotive body

Several factors affect manufacturing costs like melting temperature of the material, moulding temperature, drying temperature, back pressure, etc. In this study, processing temperature is being compared. [11] [12] [13] [14]

|

AHSS AISI 1045 |

Aluminium 5052 H32 |

SMC Grade 101 |

GMT (30% glass filler) |

LFT (PA6) |

|

Cannot be die-casted |

260-510⁰ C |

120-160 ⁰ C |

140-160 ⁰ C |

80-90 ⁰ C |

- Life cycle analysis is conducted for a material to assess the environmental impacts it has, during the different phases of its raw material extraction, manufacturing, usage, repair and maintenance and ultimately, destruction or discarding. Recyclability of a material is a good measure of assessing its environmental impacts. [17]

- Melting points of metals are very high. Hence recycling them requires much fuel (coal/electricity) and also releases a higher amount of CO2 into the atmosphere. However, composite plastics have much lower melting points and reprocessing them releases much fewer toxic gases into the atmosphere. Hence, they are much eco-friendlier than steel and aluminium. [11] [12] [13] [14]

The following table provides a comprehensive comparison of the discussed materials:

|

Tensile & Yield Strength (MPa) |

NVH |

Resistivity to corrosion |

Izod impact test |

Electrical insulation |

Thermal conductivity |

Recyclability |

cost |

Weight |

|

|

Steel (TRIP 450/800AHSS) |

800 450 |

Absorbs only very low frequencies |

Low |

1240 |

0.000007 ohm-cm (@temperature 20.0 °C) |

50 W/m-K |

yes |

Cheapest among metals |

Heaviest |

|

Aluminum (5052-H32) |

228 196 |

Better absorption than steel |

Higher than AHSS; lower than composites |

117 |

0.00000499 ohm-cm (@temperature 20.0 °C) |

138 W/m-K |

yes |

Most expensive among metals and composites |

Intermediate |

|

SMC (Grade 1) |

64.0 79.3 |

Better than metals, least in composites |

Lower than GMT |

3.20 – 15.0 J/cm |

1.00e+16 ohm-cm @temperature 90.0 – 90.0 ° |

0.250 – 0.700 W/m-K |

|

Cheapest amongst composites |

Lighter than metals; Heaviest composite |

|

GMT (4 mm thickness) |

40-145

|

Intermediate between SMC and LFT |

Excellent |

4.00 – 12.0 J/cm |

|

0.05-0.07 W/m-K |

|

Most expensive amongst composites |

Lightest composite |

|

LFT |

200 139 |

Best absorbent |

Intermediate between GMT and SMC |

0.122 – 5340 J/cm |

5.00e+14 ohm-cm |

1.52 W/m-K |

|

Cheaper than GMT |

Intermediate between SMC and GMT |

- Conclusion: Owing to the geometric complexity and high level of functionality desired in the final part, the tub design features numerous undercuts, through-holes and other sharp design features that require significant tooling action. Compression-molded GMT products have been around since the 1970s and are tough competitors in the present market. They offer superior impact, strength, creep and fatigue performance vs. shorter fiber LFRT materials — whether processed by injection or compression molding. LFRT compounds offer more design flexibility and material choices in terms of resin and reinforcements than GMT. Steel and Aluminium doesn’t plan to take a back seat to its competitors, however. It invited automakers to form a partnership to tackle a wide variety of issues, such as making the metals light, but still strong enough to resist dents. Such measures have had an impact on the automakers. Right now, after analysing the different requirements and characteristics of available options, D-LFT is best suited for the spare wheel well.

- References:

- Peggy Malnati. n.d., Spare wheel well: Functional integration: CompositesWorld. Available from: <https://www.compositesworld.com/articles/spare-wheel-well-functional-integration>. [July 03, 2019].

- Peggy Malnati. n.d., Reinforced Thermoplastics: LFRT vs. GMT: CompositesWorld. Available from: <https://www.compositesworld.com/articles/reinforced-thermoplastics-lfrt-vs-gmt>. [July 03, 2019].

- A Business Or. n.d., METALS vs. PLASTICS: And the winner is? | Design News. Available from: <https://www.designnews.com/materials-assembly/metals-vs-plastics-and-winner/208207275639641>. [July 03, 2019].

- Our Internal Machine. n.d., Composites Testing at WMT&R Inc. Available from: <https://www.wmtr.com/en.composites.html#b>. [July 03, 2019].

- Last, First. n.d., Glass fibre reinforced plastic resin tank – Knowledge – Quanzhou Neweco High Polymer Material Co. Ltd. Available from: <http://www.up-resin.com/info/glass-fiber-reinforced-plastic-resin-tank-23396184.html>. [July 03, 2019].

- Strain Can Localize. n.d., Special Process and Evolving AHSS Types | WorldAutoSteel. Available from: <https://www.worldautosteel.org/steel-basics/steel-types/evolving-ahss-types/>. [July 03, 2019].

- Linkmastermonkey.Com / Www.Linkmastermonkey.Com. n.d., The LCA of steel. Available from: <https://www.sustainableinsteel.eu/p/534/the_lca_of_steel.html>. [July 03, 2019].

- Specific Material Composition. n.d., CustomPartNet – Material Comparison. Available from: <https://www.custompartnet.com/materialcompare?m=261,264&t=34>. [July 03, 2019].

- The Hard Second. n.d., What are TRIP Steels? | National Material Company – Steel Processing Facilities. Available from: <http://www.nationalmaterial.com/what-are-trip-steels/>. [July 03, 2019].

- Last, First. n.d., Complete Molding Guidelines and Processing Conditions – PlastiComp. Available from: <https://www.plasticomp.com/long-fiber-material-processing-guide/>. [July 03, 2019].

- The Togglehander. n.d., PolyOne OnForce™ LFT NY-50LGF/001 HS Natural Polyamide 6 (Nylon 6). Available from: <http://www.matweb.com/search/DataSheet.aspx?MatGUID=98edb123bd76454b871a18d602bb11f2>. [July 03, 2019].

- The Togglehander. n.d., Overview of materials for Thermoset Polyester Glass SMC. Available from: <http://www.matweb.com/search/DataSheet.aspx?MatGUID=36ff812971894f88a6c5f9af35826dcc>. [July 03, 2019].

- The Togglehander. n.d., Aluminum 5052-H32. Available from: <http://www.matweb.com/search/DataSheet.aspx?MatGUID=96d768abc51e4157a1b8f95856c49028>. [July 03, 2019].

- Young’s Modulus of Steel. Available from: <https://www.amesweb.info/Materials/Youngs-Modulus-of-Steel.aspx>. [July 03, 2019].

- Kurcz, M. et al. (no date) ‘A CASE FOR REPLACING STEEL WITH GLASS-MAT THERMOPLASTIC COMPOSITES IN SPARE-WHEEL WELL APPLICATIONS Traditional Steel Systems Benefits and Issues with Steel’, North, pp. 1–12.

- (Whelan et al., 2012)Whelan, T. et al. (2012) ‘Sheet Molding Compound’, Molding of Thermosetting Plastics, pp. 75–85. doi: 10.1007/978-1-4615-9759-9_10.

- P. n.d., Life Cycle Analysis – The Environmental Literacy Council. Available from: <https://enviroliteracy.org/environment-society/life-cycle-analysis/>. [July 03, 2019].

- Proboscidian. n.d., The Oxidation of Aluminum – Corrosion Pro Articles. Available from: <https://www.corrosionpro.com/blog/the-oxidation-of-aluminum/>. [July 03, 2019].

- United States Postal Service. n.d., 1-10.2 Benchmarking Analysis. Available from: <https://about.usps.com/manuals/spp/html/spp1_043.htm>. [July 03, 2019].

- Bibliography

- Shibley A.M., Glass-Filled Thermoplastics. In: Lubin G. (eds) Handbook of Composites. Springer, Boston, MA. (1982)

- W. V. Titow and B. J. Lanham, Reinforced Thermoplastics Applied Science Publishers Ltd., London, (1975)

- Michael T. Takemori, Towards an understanding of the heat distortion temperature of thermoplastics, Polymer Engineering & Science, 19, 15, (1104-1109), (2004).

- H. S. Loveless & D. E. McWilliams, Physical properties of some injection moulded thermoplastics of various glass contents, Polymer Engineering & Science, (1970)

- Daniel J. Schaeffler, Introduction to advanced high-strength steels – Part I, STAMPING Journal (November 2004)

- Sugimoto, K. & Srivastava, A.K. Metallogr. Microstruct. Anal. (2015) 4: 344. <https://doi.org/10.1007/s13632-015-0221-5>

- Frank Armao, ‘Aluminium Workshop: Charpy V-notch testing—Why not aluminium?’, Practical Welding Today (September/October 2009)

- Satyendra, Steel for Automotive Applications, IspatDigest, (November 2015), accessed 21st June, 2019,

<https://www.ispatguru.com/steels-for-automotive-applications>

- Baser, B. & R. Törnqvist, “Strukturteile aus „Advanced GMT“ mit verbesserten Crash-Eigenschaften,” SKZ Conference, Würzburg, Germany (2001).

- Törnqvist, Ronnie & Burak Baser, “Structural Modules with Improved Crash Performance using Thermoplastic Composites,” SAE Congress, Paper # 2002-01-1038, Soc. of Automotive Engineers, Warrendale, Penna., USA, (March 2002).

- Delbridge et al, The Process of Benchmarking: A Study from the Automotive Industry, International Journal of Operations & Production Management · April 1995

Cite This Work

To export a reference to this article please select a referencing style below: