Abstract

This paper discusses the development of a new micropump based on microfabrication techniques that can be used for drug delivery. First, actuation methods are examined to define the working principle and the advantages/disadvantages of each actuation method, such as electrostatic, thermal, piezoelectric and magnetic. Next, examples of micropumps that employ these actuation methods are examined to see operating flow rates and power consumption. Then, a new design of a piezoelectric pump is discussed, one that uses one piezoelectric disk to operate two pump membranes. Thus, making the entire pump more efficient for drug delivery. Finally, the capital investment cost of starting a business that can make these micropumps is about $660,000.

Introduction

Microelectromechanical systems (MEMS) has been a rapidly mounting topic in recent decades, it enables researchers to miniaturize devices and manufacture them using microfabrication techniques. MEMS technology’s most interest element is known as a transducer. Transducers are defined as a device that converts electrical energy into mechanical energy and vis versa. Devices that convert mechanical energy to electrical energy are known as microsensors, such as accelerometers and gyroscopes. Devices that convert electrical energy to mechanical energy are known as microactuators, such as motors and pumps.

Get Help With Your Essay

If you need assistance with writing your essay, our professional essay writing service is here to help!

The MEMS industry has interested researchers to the idea of using common microfabrication techniques for biological purposes. One common use of these technologies is in the medical field, more specifically for drug delivery. Current methods to deliver medication to the body include oral medication, inhaler, and injections [1]. However, these methods prove to be an inefficient way to deliver drugs to the body because the medicine can be degraded before it is used and is not accurate. These methods of drug delivery are effective because they follow a pattern of sharp initial drug concentration followed by a quick decline in concentration [1]. Implantable or non-implantable micropumps can be used to combat this problem and deliver controlled, long last drug concentrations. Therefore, MEMS micropumps can be used to deliverer medicine such as insulin to the body. In this paper, actuation methods are analyzed to determine the best method of actuation for a micropump, fabrication cost and size are also taken into consideration.

Literature Review

Actuation Fundamentals

Electrostatic

The basic principle behind an electrostatic transducer is an electric charge. An electrostatic transducer is essentially a capacitor that is comprised of two conductive elements, physically separated from each other, using some kind of dielectric material [2]. The distance between the two conductors is key to how the transducer will be used, either as a sensor or an actuator. An electrostatic sensor, also called capacitive sensor works by measuring the capacitance value, which changes as a result of a force changing the distance between the two conductors. At the same time, an electrostatic actuator produces a force by applying a capacitive voltage across the two conductors. Electrostatic actuation is popular among micro-devices because of the need for small volumes and large actuation or large forces. Electrostatic transducers are great for this because they usually have a large surface area to volume ratio.

Advantages to electrostatic transducers include simplicity, low power and fast response [3]. These transducers are relatively simple due to the fact that it does not require special materials, only two conductive materials. They also take low power because actuation and sensing rely on differential voltage not current at low-frequency applications. Electrostatic transducers also offer fast response rates due to the rapid charging and discharging of time constants.

Disadvantages to electrostatic transducers include force and distance are inversely related, and a high voltage is required for static actuation [3]. When a large force is desired, the result produces a small displacement of distance, and a small force is produced when a large deflection is applied.

Thermal

Another method to produce actuation can be accomplished by adding and taking away heat. Thermal micro-actuation is based on thermal expansion or shrinkage of the structural materials subject to temperature changes [4]. Thermal expansion is the idea that heat, in various forms, can increase the volume of a material, thus increasing the length. Heat can be added in various forms, such as conduction, convection, and radiation; however, conduction and convection are the most common forms of heat transfer in thermal actuation. It is important to note that different materials have different linear expansion coefficient, thus materials for a particular application should be chosen depending on the linear temperature coefficient of expansion.

A common application of thermal expansion in micro-devices can be explained by the thermal bimorph principle. The thermal bimorph principle uses temperature difference to provide deflection in beams [5]. Thermal bimorphs consist of three main components, a heater joined between two different materials with different coefficients of expansion. The heater heats both the materials at the same rate, but because they have different coefficients of expansions, they expand at different rates. The material with the larger coefficient of expansion grows faster than one with the smaller coefficient thus making the entire beam bend toward the smaller coefficient material. This principle can also be used to open and close a diaphragm.

Advantages to thermal actuators include a large range of movement and small size [3]. These actuators tend to can have a large range of movement due to the length of the beams and the thickness of the diaphragm. Because the deflection is larger than most other actuators it is considered to be relatively small in size.

Disadvantages of thermal actuators include high power and low response rate [3]. Thermal actuator actually takes a lot of power due to the heater part of the assembly, current is being used to generate heat. Another disadvantage to thermal actuators is that they have low response rate due to the materials need to cool down every cycle. The limiting action to thermal actuators is the heating and cooling time if heat can be added and dissipated quickly then the response rate can be increased.

Piezoelectric

Another method of actuation uses the phenomena of piezoelectricity, known a piezoelectric transducer. The theory of piezoelectricity was derived from the knowledge that some materials can create an electrical charge when they undergo some stress, now known as the direct effect of piezoelectricity [6]. This knowledge lead researchers to formulate the inverse effect of piezoelectricity, the idea of applying an electrical charge to a certain material can generate a force. The piezoelectric material is the main part of a piezoelectric transducer, what makes them different from every other material is that piezoelectric materials are polarized. Piezoelectric sensors work by applying a force to the crystal, thus changing the distance between positive and negative charge sites in that crystal. This change in distance alters the overall polarization of the crystal, which can be measured for sensing. On the other hand, piezoelectric actuators work by applying a charge to the crystal, thus changing the distance between positive and negative charge sites in that crystal. This change in distance leads the elastic strain, and therefore, the deformation of the crystal. The polarity is very important in piezoelectric transducers because it allows sensors and actuators to know if they are reacting to, or producing, a compressive or tensile force.

Advantages to piezoelectric actuators include high force output, fast response, and low power dissipation [3]. Some piezoelectric actuators have seen able to see high force outputs, such as 10 micronewtons to 1 millinewton. Piezoelectric actuators also offer fast response rates due to the rapid charging and discharging rates of the materials. Another advantage is that they offer low power dissipation.

Disadvantages to piezoelectric actuators include complex fabrication and depolarization [3]. The main disadvantage to these kinds of actuators is that they are complex and costly to fabricate, due to the specialized materials that are needed. The material must be able to be polarized and the process of polarizing takes time is costly. The polarizing process involves the crystal being exposed to a strong electric field at high temperature for a certain amount of time. Another disadvantage is the risk of depolarization because polarization is the key to this kind of actuator, it is important to remember to protect from depolarization. Exposer to large forces,

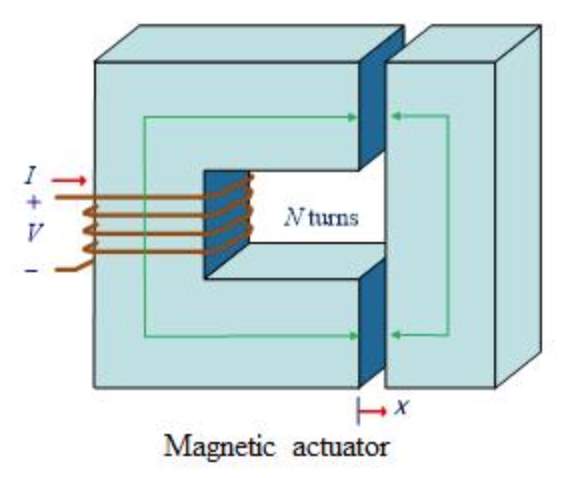

Magnetic

Magnetic transducers use, as its name suggests, magnetization to sense and actuate. Magnetization, or magnetic polarization, is the density of magnetic dipole moments that are induced in a magnetic material when it is placed near a magnet [7]. The magnetic effects of a material can also be produced by passing an electrical current through the material. Magnetic transducers in general consist of soft magnetic cores and are activated by currents in energized coils or use permanent magnets. A wire carrying a current in the presence of a magnetic field will experience the Lorentz force. The force generated is large, however, electromagnetic actuation requires external magnetic field usually in the form of a permanent magnet.

The only advantage to magnetic actuators is their ability to produce a high force output [3]. The force in magnetization can be increased in multiple ways, they are all modeled by the Lorentz equation. In the equation, it can be seen that if the length of the wire, magnetic field or current is increased the force exerted by the device is also increased.

Disadvantages of magnetic actuators include high power consumption and fabrication complexities [3]. The high force output comes with a downside because it requires high current, the actuators consume a great deal of power. Another disadvantage is that magnetic actuators are quite complex to fabricate, this due to fact that thick conductors are needed and not all magnetic materials can be deposited with current fabrication techniques. Special materials are also needed for fabrication causing the cost of fabrication to increase.

Pumps

Electrostatic

An excellent example of an electrostatically actuated micropump is Zengerle, Ulrich, Kluge, M. Richter and A. Richter’s bidirectional silicon micropump [8]. Their design consists of two essential parts, an actuation unit, and a valve unit. The actuation unit is comprised of a diaphragm and a counter electrode. Electrostatic diaphragm pumps work by applying a voltage to the diaphragm to bend it toward the counter electrode, creating suction. The voltage is then turned off to allow the diaphragm to return to its original position, creating positive pressure. The valve unit comprises of two passive check valves and two nozzles/diffusers. The nozzle/diffuser allows for an increase in velocity to open the check valves. A supply voltage of 150 to 200 volts is applied to produce frequencies of 0.1 to 800 Hertz. This design has achieved a maximum pump rate of 160 microliters per min, while only consuming less than 5 milliwatts of power. The final design of the pump was 7 millimeters by 7 millimeters by 2 millimeters. While the design allows for two-way flow, we will only be looking at single directional flow for simplicity and because medical pumps only need single directional flow.

Thermal

A great case of a thermally actuated micropump is Jeong and Yang’s thermopneumatic micropump with a corrugated p+ diaphragm [9]. Like electrostatic pumps, thermal pumps consist of two essential parts, an actuation unit, and a valve unit. In Jeong and Yang’s design, their valve unit operates on the same principle as in previous designs, with a pair of nozzles/diffusers, but they oriented differently. However, the difference is the actuation unit. The actuator unit consists of a heater, a diaphragm, and a sealed cavity. Thermally actuated micropumps work by powering an ohmic heater that increases the temperature and; therefore, volume and pressure in the sealed cavity. This increase in pressure causes the diaphragm to expand and expend the fluid out of the pump chamber. The heater is then turned off to decrease the temperature and; therefore, the volume and pressure to allow the diaphragm to return to its original position. This creates positive pressure on the suction side of the pump allowing to draw up the fluid and restart the cycle. Jeong and Yang’s final design is 4 by 4 millimeters by 450 micrometers, not including the valve unit. An input voltage of 8 volts is applied to produce a frequency of 4 Hertz. With this power supply, a flow rate of 14 microliters per minute and a pressure of 2500 pascals was observed [9].

Piezoelectric

Van Lintel, Van Del Pol, and Bouwstra were the first to attempt the large-scale fabrication of piezoelectric micropump based on the micromachine of silicon [10]. Their goal was to develop a more reproductive and stable piezoelectric micropump. Unlike previous designs, they took a more vertical approach to the configuration of their pumps. The design consists of three layers, a glass top and bottom layer, and a silicon layer that contains the valves and pump chamber. The piezoelectric disc is attached to the glass top, making the glass top a makeshift membrane. The piezoelectric micropump operates by applying a voltage to the piezoelectric disc, causing it to strain and bend downwards. The volume of the pump chamber is decreased, and the liquid is forced through valve 2, while valve 1 checks the return flow. Then the voltage is switched off, so the membrane can adopt its original shape and fluid will be drawn through valve 1 while valve 2 checks the return flow. The entire configuration takes up a volume of 4100 cubic millimeters. An input voltage of 125 volts is applied to produce a frequency of 0.1 Hertz. With this power supply, a flow rate of 0.6 microliters per minute and a pressure of 2400 pascals was observed [10].

Magnetic

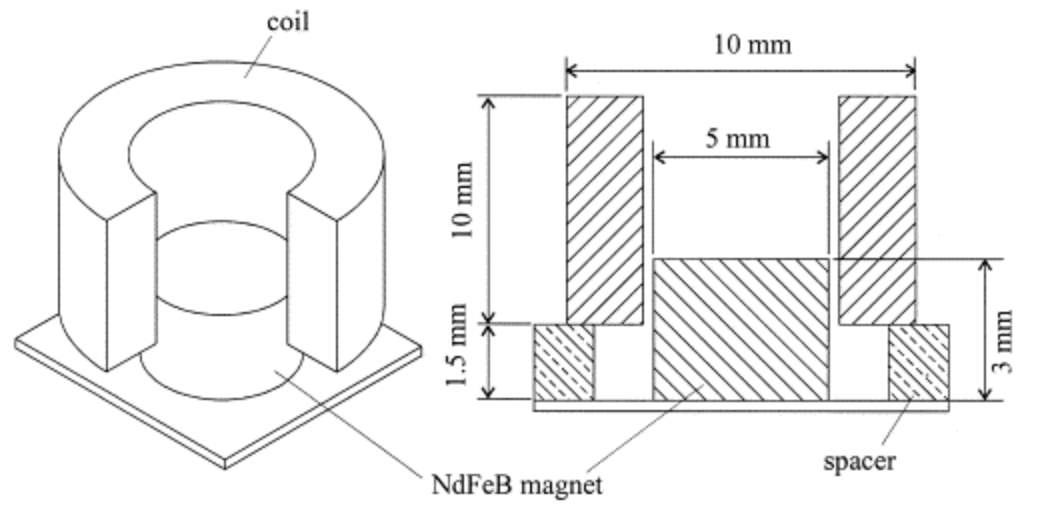

Another example of a micropump was proposed by Bohm, Olthuis, and Bergveld, they designed an electromagnetic micro pump [11]. Their goal was to design a plastic micropump than can be produced using conventional production techniques and materials. Unlike other designs discussed, this design consists of two molded valve units and a membrane on top, to create the pump chamber. The additional valves allow the pump to close some parts of the pump to minimize the dead volume in the pump chamber. An electromagnetic actuator consisting of a permanent magnet placed in a coil was used in combination with a flexible micropump membrane. The material used for the magnate is Neodymium (NdFeB) but it is considered a rare earth metal. Power consumption was found to be 0.5 watts while achieving flow rates of 100 microliters per minute. A relatively large volume is occupied by the electromagnetic coil, therefore the micropump final dimensions are 10 by 10 by 8 millimeters, making the pump assembly large [11].

Summary

The main component of every micropump is the membrane and how it is actuated. The electrostatic pump is actuated by the electrostatic attraction force. The deflection of the diaphragm can be easily controlled by the applied voltage, and the response time is fast. However, the output pressure and the volume stroke of the electrostatic micropump are small compared with others because large volume stroke requires high voltage input. The piezoelectric pump is actuated by the deformation of the piezoelectric material. This actuation method has advantages of the large force and the simple structure over others. In order to obtain a large deflection of the actuator diaphragm, however, the high drive-voltage is demanded. Thermal micropumps are great because they have a large deflection leading it to have a large volume stroke. Thermal pumps are not ideal for certain situations due to the raising of the temperature and the low pump rates. Although the electromagnetic actuation method has the advantages of the long working range and the high field energy density, the fabrication of the device is complicated, and the size of the pump is on the large side.

Taking all of this into consideration, the piezoelectric actuation method is the best because the disadvantages can be worked around or designed to be a benefit.

Proposed Design

In this research, the aim is to produce a device that is used to deliver drugs, such as insulin to a body. While many devices exist, this research’s purpose is to improve previous designs to use half the power and produce double the flow rate. This is accomplished by using one piezoelectric disk to actuate two micropump diaphragms.

The design consists of three main parts:

- Piezoelectric disk

- Diaphragm and pump chamber

- Valve and nozzle/diffuser

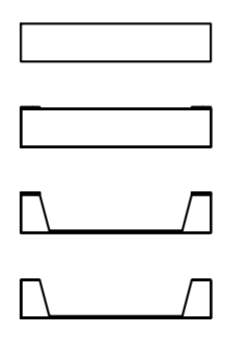

Fabrication

To simplify the fabrication process, the entire micropump assembly requires six different wafers. The fabrication process uses basic MEMS manufacturing methods such as etching, deposition, and photolithography. The only materials that will be needed are silicon wafers, PZT disks, and glue.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

The first part of fabrication entails the manufacturing of the valve and nozzle/diffuser. Step 1 is to obtain a clean silicon wafer that is ready to be etched. In step 2, a silicon oxide mask is deposited and patterned, leaving two bare circles. Step 3 requires the wafer to be anisotropically wet etched using a potassium hydroxide solution, to produce two circular cones. It is important not to etch all the through the wafer; therefore, the etching process will need to be stopped and rinsed. In step 4, another silicon oxide layer is grown. In step 5, the silicon oxide layer is photolithographically patterned to reveal bare silicon. Step 6 requires the wafer to be anisotropically wet etched using a potassium hydroxide solution, to produce one circular cone and one lever (that will be used as a passive valve). The entire wafer should be rinsed and cleaned, ready to be attached to another silicon wafer. This entire first part of the fabrication process needs to be done four times per micropump.

Step 1

Step 2

Step 3

Step 4

The second part of fabrication entails the manufacturing of the diaphragm and pump chamber. Step 1 is to obtain a clean silicon wafer that is ready to be etched. In step 2, a silicon oxide mask is deposited and patterned, leaving one big bare circle. Step 3 requires the wafer to be anisotropically wet etched using a potassium hydroxide solution, to produce one big circular cone. It is important not to etch all the through the wafer; therefore, the etching process will need to be stopped and rinsed. However, the last layer of silicon needs to be thin to allow for maximum deflection of the diaphragm. The entire wafer should be rinsed and cleaned, ready to be attached to another silicon wafer. This entire second part of the fabrication process needs to be done two times per micropump, creating two pump chambers and diaphragms.

Micropump Assembly

There 7 layers in the assembly of this micropump. Once all of the different wafers are fabricated, one diaphragm and two valves are glued together using a thin layer of SU8-5 adhesive. The same can be done with the remaining wafers, creating two separate micropump assemblies. The heart of the micropump, the PZT disk is adhered to one of the micropump assemblies along with an O-ring, to give support. The other pump assembly is adhered to the PZT disk and O-ring, making the entire double piezoelectric micropump.

Operating Principle

This design of a double piezoelectric micropump allows one piezoelectric material to operate two micropumps. As a voltage is applied to the piezoelectric material, the piezoelectric material expands and causes the diaphragms to expand, as well. When this happens, the diaphragms go up and down together. More specifically, as the top diaphragm goes up, the bottom diaphragm goes down. This design allows the entire micropumping unit to continuously pump fluid. For example, as the top pump chamber fills with fluid, the bottom pump chamber pushes its fluid out. In essence, this pumping unit can pump at the same rate as other pumping units, but at half the power costs. Or the double piezoelectric micropump can pump double the flow rate at the same power when compared to other micropumps.

Business Plan

To start a company that makes this particular micropump a business plan primarily focusing on the material, manufacturing equipment, overhead costs, and labor need to be discussed.

- Modutek Corporation’s wet etch table: $250,000

- Karl Suss’s photolithography equipment: $150,000

- Headway Research Incorporation’s phots resist table: $5,000

- Materials and Overhead: $5,000

- Labor: $250,000

In total, the cost associated with manufacturing this particular micropump is about $660,000. These numbers were gathered from the internet and; therefore, could be old and inaccurate. Additionally, more or unanticipated equipment maybe need and is not reflected in this business plan.

Conclusion

After looking at common mechanical actuation methods and pump, piezoelectric was chosen to actuate the micropump for the application of drug delivery due to its advantages over other types of actuation. Piezoelectric was chosen for its relatively simple structure and large output force. The double piezoelectric micropump was designed to minimize the disadvantages of the specific actuation method. The double pump design made the pump about twice as efficient when compared to similar pumps. The pumps silicon construction allows it to be compatible with the body; therefore, not required and special materials.

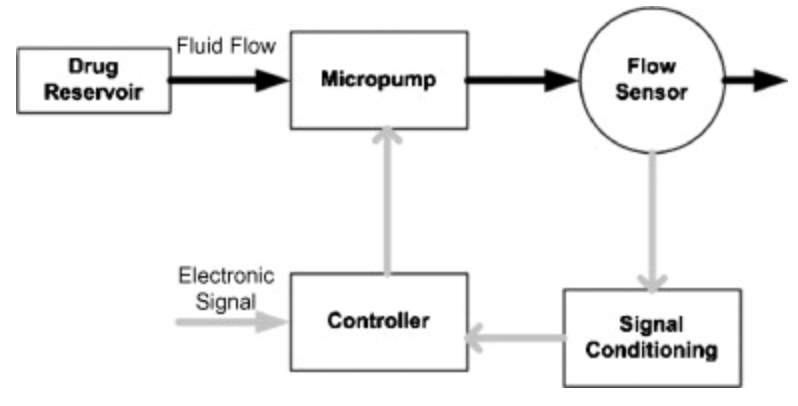

Further future work would be to integrate the double piezoelectric pump into a drug delivery system. The drug delivery system would consist of a drug reservoir, a micropump, valves, microsensors, microchannels and necessary. Below is a simple schematic of an integrated drug delivery system.

References

- Joshitha, C., et al. “A Review on Micropumps for Drug Delivery System.” 2017 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), 2017, doi:10.1109/wispnet.2017.8299745.

- Knospe, Carl R. “Capillary Force Actuation: A Mechatronic Perspective.” Control Technologies for Emerging Micro and Nanoscale Systems Lecture Notes in Control and Information Sciences, 2011, pp. 201–218., doi:10.1007/978-3-642-22173-6_12.

- Liu, Chang. Foundations of MEMS. Prentice Hall, 2012.

- Que, L., and A. Baroutaji. “Thermal Actuation.” Reference Module in Materials Science and Materials Engineering, 2016, doi:10.1016/b978-0-12-803581-8.00540-3.

- S. Zimmermann, J.A. Frank, D. Liepmann, A.P. Pisano A planar micropump utilizing thermopneumatic actuation and in-plane flap valves. Proceedings of the 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS): MEMS 2004 Technical Digest, Maastricht (2004), pp. 462-465.

- E. Stemme, G. Stemme. A valveless diffuser/nozzle–based fluid pump Sens. Actuators A: Phys., 39 (2) (1993), pp. 159-167.

- T. Pan, S.J. McDonald, E.M. Kai1, B. Ziaie. A magnetically driven PDMS micropump with ball check valves. J. Micromech. Microeng., 15 (2005), pp. 1021-1026.

- R. Zengerle, J. Ulrich, S. Kluge, M. Richter, A.Richter. A bidirectional silicon micropump. Sens. Actuators A, 50 (1995), pp. 81-86.

- O.C. Jeong, S.S. Yang. Fabrication and test of a thermopneumatic micropump with a corrugated p+diaphragm. Sens. Actuators A: Phys., 83 (2000), pp. 249-255.

- H.T.G. Van Lintel, F.C.M. van De Pol, S.Bouwstra. A piezoelectric micropump based on micromachining of silicon. Sens. Actuators., 15 (2) (1988), pp. 153-167.

- S. Bohm, W. Olthuis, P. Bergveld. A plastic micropump constructed with conventional techniques and materials. Sens. Actuators A: Phys., 77 (1999), pp. 223-228.

Cite This Work

To export a reference to this article please select a referencing style below: