Organisations are currently faced with high pressure to ensure good quality and satisfaction of customers while simultaneously reducing any incompetence or errors. Customers are the driving force behind the economy and organisations must accordingly seek to maximise their customer base and at the same time uphold the current one. A multitude of methods and instruments can be applied to ensure such results aid in company development and high-quality levels. One such method is the Six Sigma, devised during the 80s by Bill Smith and Bob Galvin for Motorola. The notion of Sigma comes from statistics, indicating the standard deviation from the mean in terms of a certain variable. Accordingly, Six Sigma refers to the standard deviation’s distance times six, and to reach this goal the amount of defects produced by a process must not exceed 3.4 for every million. The definition of a defect is any quality not included in customer specifications. This tool is highly effective for seeking perfection and continuous development, thanks to its dynamic nature and role in developing other business and statistical tools, as its minimised costs, production time and defects while ensuring product development, market shares and a wide customer base. It can be implemented at any phase of the administration and production processes (Smetkowska and Mrugalska 2018).

Get Help With Your Essay

If you need assistance with writing your essay, our professional essay writing service is here to help!

After choosing the project idea, the next step is to convert it to a functional project. Generally, the most efficient method is to employ a tactical approach to the problem, with a well-coordinated methodology based on improvement which would guide the process from when the problem is first identified, right through to the introduction of possible solutions directed at the root issues (Golding and Walsh 2011).

Quality management can involve a wide variety of tools, of which two of them may be regarded as methods for achieving quality improvement in relation to the concept of the Six Sigma. These are simply DMAIC (Define-Measure-Analyse-Improve-Control), and DMADV (Define, Measure, Analyse, Design, and Verify). The DMAIC method is concerned with process improvement in relation to the Deming Cycle. It involves 5 interconnected phases, and affects multiple areas of the organization using the improvement process (Smetkowska and Mrugalska 2018).

DMAIC is amongst the more popular models of improvement, and delivers the foundation and structure a project idea needs in order to be successful. The process flow of DMAIC is illustrated in Figure 1. (Golding and Walsh 2011).

Figure 1. DMAIC, adopted from (Walsh 2009).

As in regards of tools and techniques that are used during the process, Karout and Awasthi (2017) suggest the ones reflected in the below Table 1.

|

Phase |

Tools and techniques used |

|

Define |

Critical to quality (CTQs) – Establish metrics customers value most SIPOC – Identify limits in the business process |

|

Measure |

Pareto charts – Highlight the solutions for issues in order of rank Control charts Process map |

|

Analyze |

5-Why Technique – Separate symptoms from causation Cause and Effect Diagram – Establish the root cause of the issue Interrelationship Diagram – Establish the relationship formed between the causes. |

|

Improve |

Quality Function Deployment – Aid in enhancing the design phase and achieving client satisfaction. |

|

Control |

Measurement Metrics |

Table 1. Techniques used in DMAIC, adapted from Karout and Awasthi (2017).

DEFINE

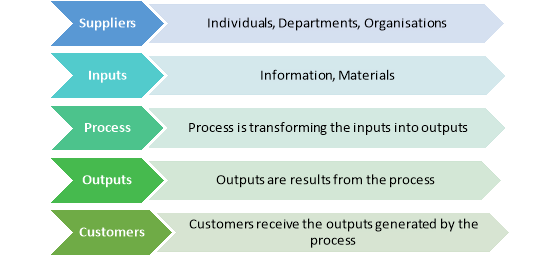

In the DMAIC model, the define phase concentrates on establishing the charter of the project. Some characteristics such as objective, timeline, goals, expected outcomes, execution plan, problem statement and the project team, all in relation to the core business strategy and customer requirements, are all confirmed in this stage. The project is initialised with the careful analysis and recording of process mapping, inputs, output, main suppliers, key elements affecting quality according to a SIPOC analysis, and customer base (Sharma et al. 2018). In its own turn, SIPOC diagram helps to understand where business stands in satisfying customer requirements:

Figure 2. SIPOC, adopted from (Walsh 2009).

Afterwards, the sigma level, that is, the performance of process, is identified using sampling followed by a Pareto analysis which would bring out any major defects. Then, these defects are analysed to pin point their possible causes using diagrams for Cause and Effect. Root causes are analysed with the CRT tool. Design engineers assist the team to further analyse and create observations that would allow for ways of process improvement. Another process performance sample is taken in order to observe the performance and process control after those recommendations are management approved and executed. Understanding of the main process elements, the design process, components of outputs and inputs, and causes for defects, is crucial for advancing the process quality (Golding and Walsh 2011, Sharma et al. 2018).

MEASURE

This phase is based on information and research in relation to the processes which require more development. In particular, it is concerned with information that would aid in understanding of how every aspect of the process operates, such as by examining the specifications of suppliers, the customer requirements, and by identifying key problem causing areas. This can be achieved, for example, using a process map, whereby failure mode and effect analysis (FMEA) is carried out so as to analyse potential risks. The measure phase aims to collect as much data so that proper analysis can occur of all the differences in the control phase, while at the same time assessing the development so that concrete results can be produced for the management. Similarly, it is of importance that the measurement system is kept in check, with all the data being collected ethically and from verified sources (Smetkowska and Mrugalska 2018).

ANALYZE

This phase is concerned with the analysis of data as opposed to gathering the information. It employs various tools and methods to establish root causes of problems and assess the risks. After the analysis, several samples need to be carried out in order to confirm the analysis and prove potential issues to be actual problems. It is necessary to highlight the process capability and to revaluate existing goals in leu of new data gathered from the measure phase, as well as initiate analysis of the root causes impacting process variability. The level of satisfaction of customer requirements because of this process is established by measuring the process capability, as such, the “sigma” of the process, which is a major part of future planned improvements. (Smetkowska and Mrugalska 2018).

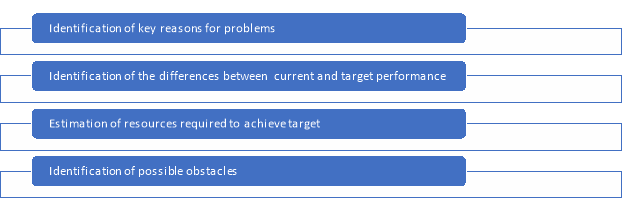

Hahn et al. (1999) argue that defects root causes and the level of their impact should be identified during the analysis stage of baseline process capability. This should be followed by efficient actions at the next phase of DMAIC model of improvement. The following actions can be suggested as main outcomes during the stage:

Figure 3. Main outcomes of ANALYZE phase, adopted from (Hahn et al. 1999).

IMPROVE

This stage relies on using the information gathered from the previous stage to foster an action plan which would improve the financial and customer relation aspects, along with the organisation itself. Any potential solutions acquired during the action plan are presented and carried out, but not on a grand scale immediately as they must first be tested on small areas so that any adjustments can be carried out, and the analytical work is proven correct. (Smetkowska and Mrugalska 2018).

The Improvement phase is characterised by optimum ways of reducing defect levels and implementation of changes in order to eliminate the imperfections. This can be done through application of different techniques such as preparation of work division structure; development, testing and selection of the best one; design of the implementation plan (Hahn et al. 1999).

CONTROL

This stage concerns the verification that previous implemented changes are verified to improve the process, by checking the quality and confirming the results are deemed unremitting and satisfactory. As well as, it monitors the process state in the upcoming future so that it stays on track in relation to the set objectives and prevent accidents beforehand. Statistical process control is one example of a control system which needs to be introduced, and the entire process must be monitored at all times. Phase control charts are put in place to establish how controllable the process is (Smetkowska and Mrugalska 2018). Documentation of standardization plan, confirmation of improved procedures, transferring the ownership of the relevant teams after the completion of the project – are some of the major elements of this phase (Hahn et al. 1999).

Find Out How UKEssays.com Can Help You!

Our academic experts are ready and waiting to assist with any writing project you may have. From simple essay plans, through to full dissertations, you can guarantee we have a service perfectly matched to your needs.

View our academic writing services

Moreover, every stage of the DMAIC process should be accomplished by tollgate reviews. They are crucial to have because of the links between the ongoing project and overall corporate targets. Timely tollgate reviews give opportunity to all the parties involved in the process to tune the process I the most efficient manner. Below Table 2 highlights some of the major benefits of having tollgates within the DMAIC structure:

|

Keep organisation priorities in mind while observing work presented by team |

|

Ensure project remains on course |

|

Supply the team with guidance |

|

Establish solutions for organizational issues detrimental to the project |

|

Carry out critical timing checks to ensure project deadlines are met |

|

Know beforehand what the upcoming phase of the project will require |

|

Authorize essential resources for project completion |

Table 2. Tollgates benefits, adopted from (Golding and Walsh 2011).

Finally, DMAIC should include some other additional steps, for instance developing a statement concerning various important business matters and outside influences, using that to form a hypothesis, creating predictions stemming from it and testing them further before carrying out experimentation and statistical analysis (Smetkowska and Mrugalska 2018).

References

- Smętkowska, M. and Mrugalska, B. (2018) ‘Using Six Sigma DMAIC to improve the quality of the production process: a case study’, Procedia – Social and Behavioral Sciences, 238, 590 – 596, available: doi: 10.1016/j.sbspro.2018.04.039.

- Hahn, G.J., Hill, W.J., Hoerl, R.W. and Zinkgraf, S.A. (1999) ‘The Impact of Six Sigma Improvement-A Glimpse into the Future of Statistics’, The American Statistician, 53 (3), 208-215.

- Karout, R. and Awasthi, A. (2017) ‘Improving software quality using Six Sigma DMAIC-based approach: a case study’, Business Process Management Journal, 23(4), 842-856, available: https://doi.org/10.1108/BPMJ-02-2017-0028.

- Sharma, P., Malik, S.C., Gupta, A. and Jha, P.C (2018) ‘A DMAIC Six Sigma approach to quality improvement in the anodising stage of the amplifier production process’, International Journal of Quality & Reliability Management, 35 (9), 1868-1880, available: https:// doi.org/10.1108/IJQRM-08-2017-0155.

- Walsh, P. (2009) ‘Problem Solving Tools and Techniques’, BST115, National University of Ireland, Galway, unpublished.

- Golding, G. and Walsh, P. (2011) ‘Quality Science-Six Sigma’, BST114, National University of Ireland, Galway, unpublished.

Cite This Work

To export a reference to this article please select a referencing style below: